Co-efficient of Friction (COF) defines the sliding interaction between two surfaces. Static Friction and Dynamic…

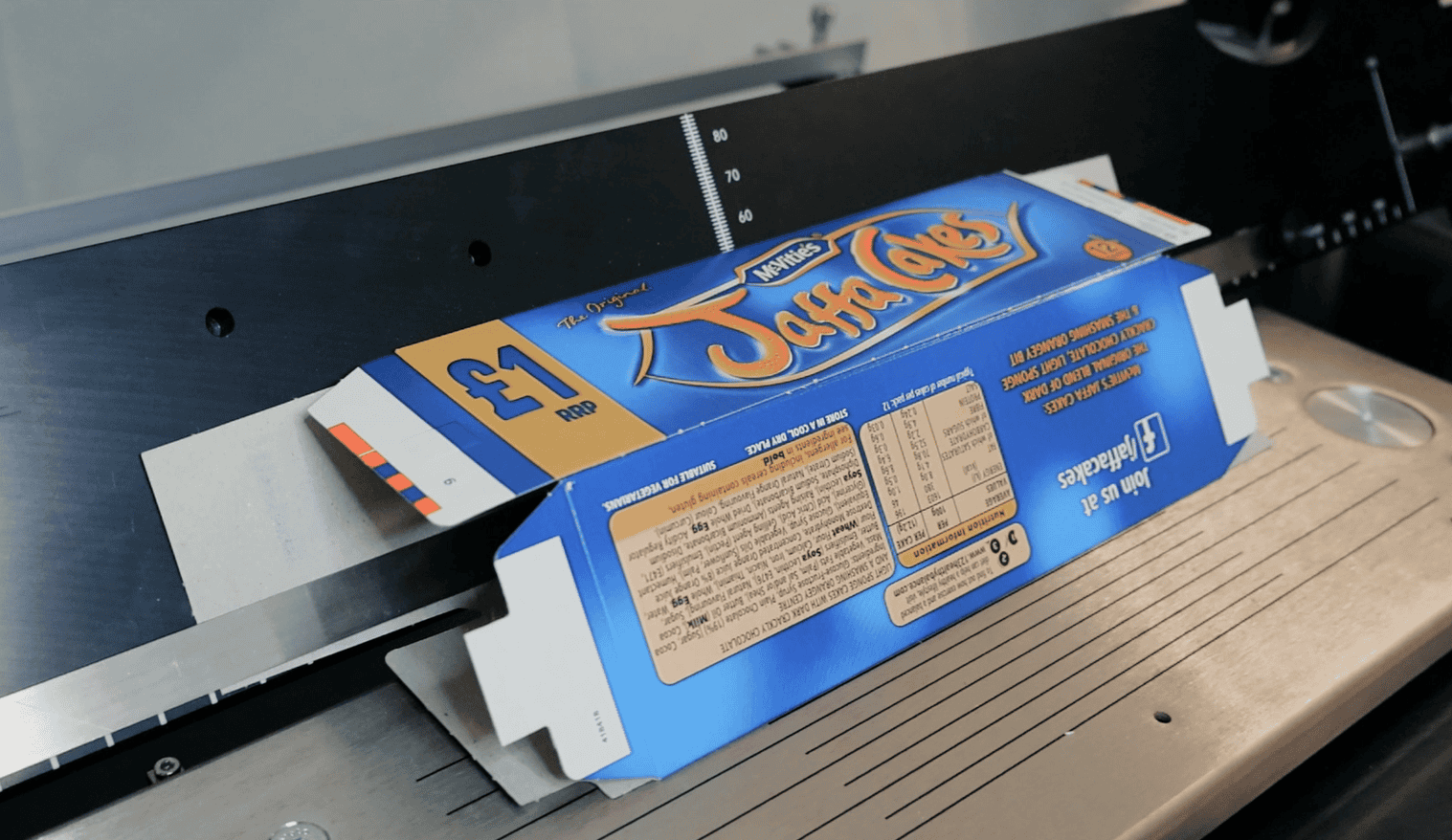

HOW TO TEST CARTON CREASES

FOR CREASE STIFFNESS / BREAKING, BOX FORMING STIFFNESS, SPRINGBACK AND SURFACE FRICTION.

The RDM Laboratory Carton Tester (LCT) is the ultimate 4-in-1 test instrument for measuring crease stiffness / breaking*, box forming stiffness, crease springback and sliding angle friction.

Creases cut in flat carton board must be consistent in quality to ensure smooth running on automated carton erecting machinery and for reliable box performance under compression loading.

When creases are inconsistent the constructed carton can split and break during forming or under load, can bulge or not form correctly, or can be misshaped.

Cartons are often erected on automated packing machinery that fold, glue and fill the product contents. However, downtime can occur when running cartons with inconsistent creases. This is expensive to both product packers and ultimately to the carton suppliers.

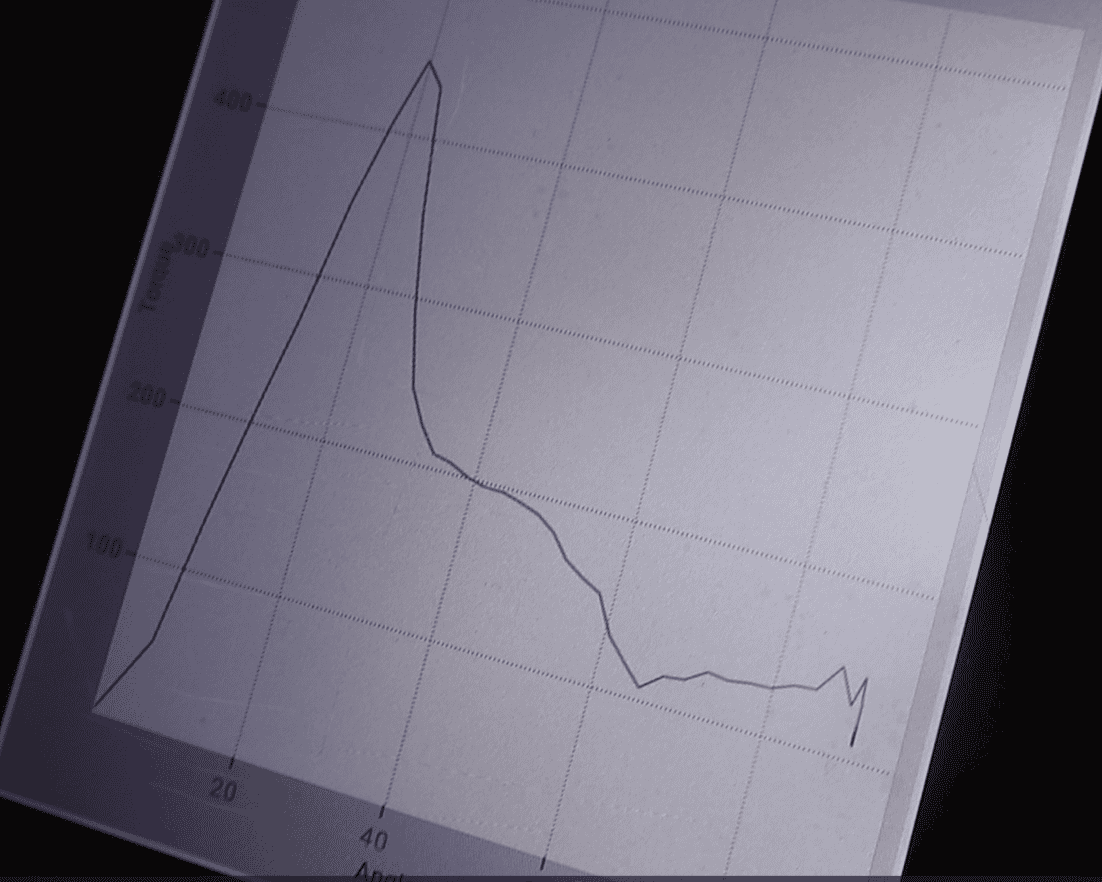

* Crease stiffness/breaking terms are used interchangeably, they define the point at which a crease being opened transitions from elastic to plastic phase i.e. when permanent change has occurred, in a torque v bending angle test.

CARTON BOARD

Carton board is used in both primary and secondary packaging applications in multiple industries including food, beverage, pet food, medical technology, pharmaceuticals, and a wide range of household and industrial applications.

It’s protective properties, printed branding opportunities and recyclability make it a great choice for high volume consumer goods that are processed in high-speed packing line.

Carton board is produced from paper-based fibres typically with a mix of virgin and recycled fibres. Virgin fibres are longer and stronger, so the introduction of high proportions of recycled materials can create performance challenges. Fibres are processed such that the finished board has a defined machine direction known as MD (Machine Direction, down the length of the fibres) and a transverse direction known as TD (Transverse Direction, across the fibres). Creases behave differently depending on the board direction.

Creases in TD tend to experience more fibre breaks than those in MD at the outer side of the crease as it is forced from flat (0 degrees) to the required angle (e.g. 90 degrees). This results in a well-defined yield point in a graphical plot of stiffness versus folding angle and a carton that forms well.

The inside of a TD crease sees more fibre compression as each fibre is squashed into a smaller space which may cause the folding torque to increase as the carton angle approaches 90 degs.

Creases in MD can suffer more performance issues since there is less fibre breaking during forming of the carton. The material fibres around the crease can roll on one another, generating a less well-defined crease and in some cases causing high springback forces characterised by the desire of the carton to return towards the original flat shape.

TESTING

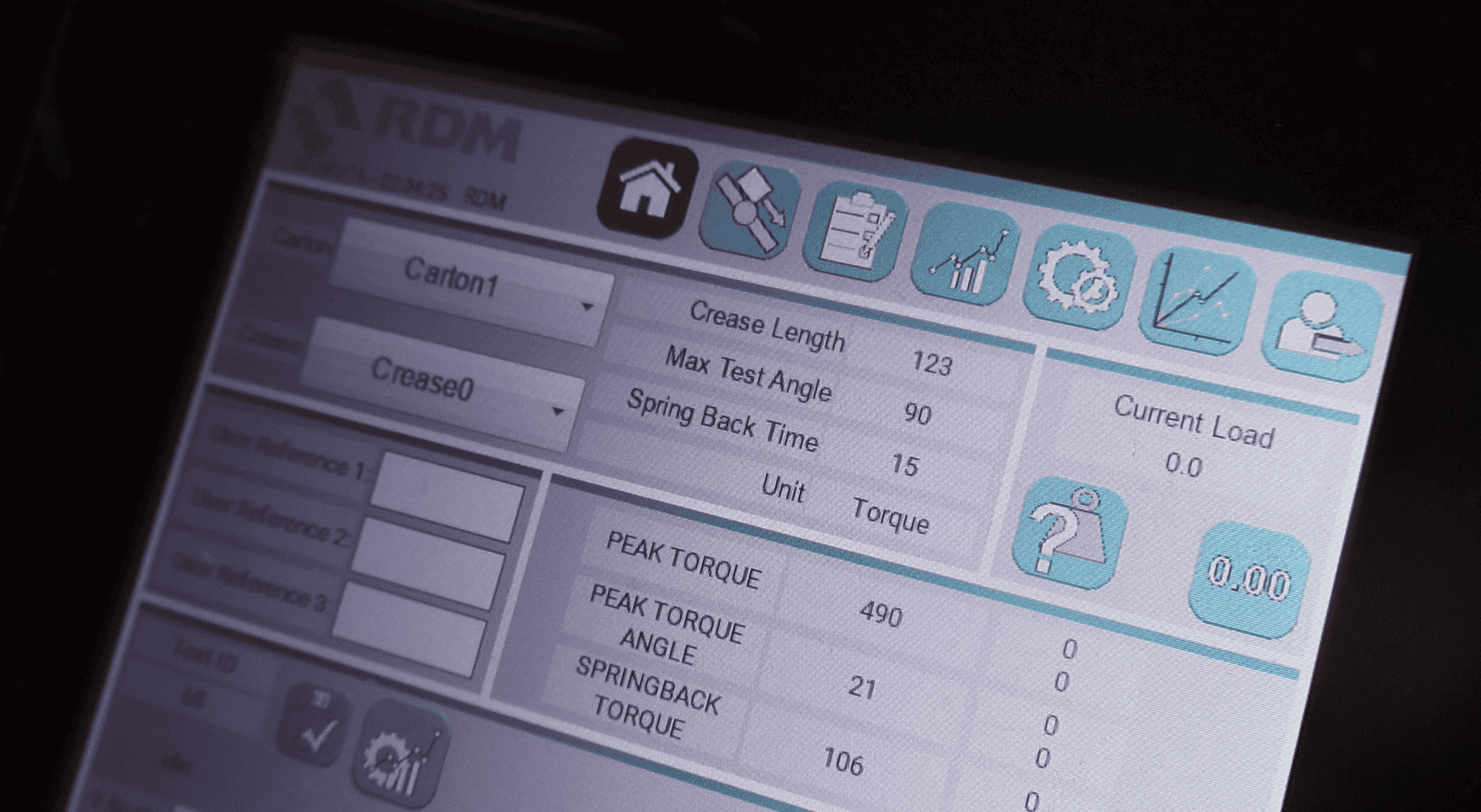

When testing individual creases and complete box forming, the RDM Lab Carton Tester measures and records Peak Torque, Peak Torque Angle, and Springback Torque. Peak Torque is the maximum force detected when folding the crease, in units of mN.m (milli-Newton Metres). Peak Torque Angle is the folding angle at which Peak Torque occurred, a low value would suggest a brittle break compared to a higher value. Springback Torque is the elastic turning force driving the crease back towards the original flat shape.

Traditional crease stiffness test methods involve cutting a narrow sample including the crease from the complete carton, loading in a stiffness testing instrument and measuring the maximum bending force to fold the crease. However, with narrow samples it is hard to detect small differences between good and bad creases, and inconsistencies along the length of a crease can be missed.

The RDM Laboratory Carton Tester (LCT) measures the complete carton length in one go (up to 600mm wide) providing valuable quality control data to define acceptable stiffness values. Used by both brand owners packing their goods and carton manufacturers, the data provides a common standard that can be compared and agreed upon, thus saving money from wasted materials, brand reputation damage from faulty packaging, and productivity downtime. The LCT is independent of operator influence, ensuring reliable data that can be acted upon confidently.

Not all carton creases are critical to the finished product performance, but typically one or two long length creases have a dominate effect on the functioning of the carton. These can be easily identified, and a testing regime implemented that captures the critical data.

In the carton manufacturing industry, die-cutting machine operators can adjust the depth of cut by applying different grades of tape to the back of the cutting board. This skilled task requires accurate data to ensure all impressions of the cutting board are producing equal quality carton creases. The LCT is the tool needed to collect this data quickly and accurately.

To implement the LCT, preliminary testing of good and bad batches of cartons is undertaken to characterise acceptable values for a crease, thereby setting pass / fail limits to control the future quality. This work can be done with the help of the instrument supplier.

In the longer term, both carton manufacturers and product packers can harmonize quality expectations against data driven standards free from interpretation and human error. The ROI (return on investment) of the instrument will be enjoyed for years to come through improved customer / supplier relationships and the ability of carton manufacturers to present quality data attracting new clients.

FEATURES

The LCT can be operated following basic training, with simple sample loading, one key press operation, automatic data saving with date/time stamp, graphical display, tabular display, pass/fail assessment against pre-loaded high/low tolerances, and data transfer to csv and pdf reports.

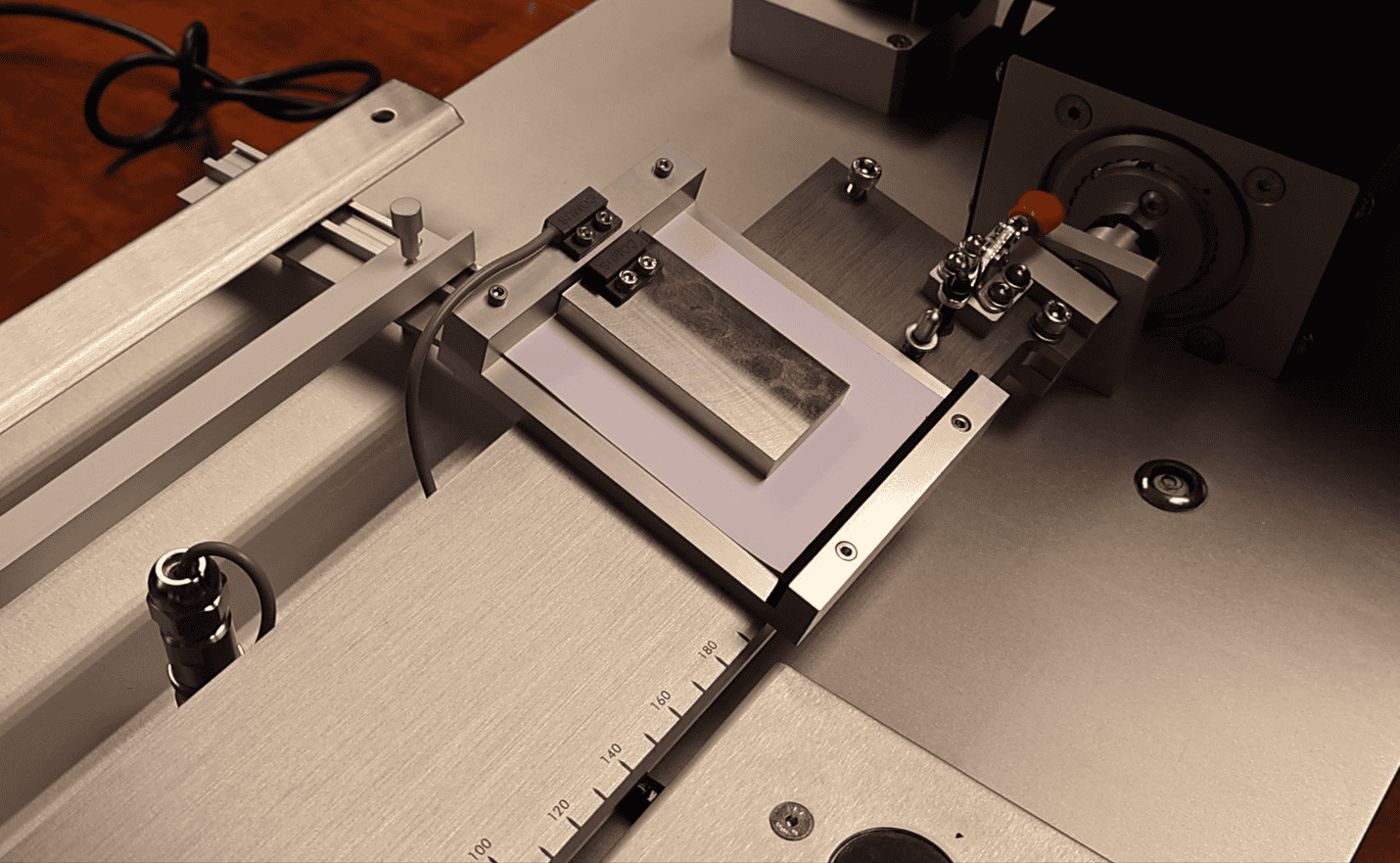

An optional Friction Testing attachment can be added to LCT enabling Static Coefficient of Friction tests on board samples. The attachment comprises a test bed that fixes to the rotating plate of LCT, and a test sled. Samples are cut and loaded, LCT then measures the angle at which the sled slips. The tangent of the angle is the static coefficient. A small angle indicates high slip, and a greater angle indicates low slip.

The LCT is manufactured by RDM Test Equipment and is available throughout the world via direct sales/service offices or local distributors. There is just one standard model that includes a GUI (Graphical User Interface) keeping things simple to use and complete. An optional Friction Test attachment extends the capability to measuring static coefficient of friction of carton board, employing the inclined plane test method.

RDM Test Equipment provide pre and post-sales support direct from UK and USA offices and from multiple distributors around the world.

Q&A

Who uses the LCT?

Quality and Production teams in carton manufacturing and Quality Control within brand owners / product packers. Also useful for Research and Development of new carton packaging formats. The existing install base reaches all continents, with frequent use in Europe. Existing users include Unilever, Procter & Gamble, DS Smith, Smurfit Kappa, and Westrock.

What is the history of the LCT?

During the 1980’s, powdered laundry soap packed into stiff cartons presented the original challenge which was solved by the first designed instruments that went on to be manufactured for many years by Newton Instruments known as the Newton Carton Tester. Around 2010, the instrument was acquired by Cerulean (now part of the Molins Group) to fit into their tobacco industry testing range. The electronics supply chain issues of the Covid era brought it to a temporary end, whereupon it was revived and redesigned by RDM Test Equipment to the current instrument.

How is measurement data used by carton manufacturers?

Initial studies are undertaken to define and agree the required pass / fail limits for the critical creases only in a pack format. Thereafter, the die cutting machine operator can setup and run the die cutting process and immediately check compliance with the set standard. If the creases are out of specification, adjustments to the cutting plate can be made and more samples tested. A local standard operating procedure can be defined and followed to ensure waste is reduced and recall of batches for the reason of failed creases becomes a thing of the past.

Is there a recognised testing standard for the LCT?

The LCT follows a common set of parameters and therefore an internationally recognised standard has never been needed. Paper-based test sample materials are typically affected by environmental conditions such as temperature and humidity so storage and pre-conditioning of samples should be standardised for which both ASTM and ISO standards exist.

How is the LCT maintained?

Annual service and calibration which is available either directly from RDM Test Equipment or the local instrument supplier. This service includes providing a traceable calibration certificate that can be used within a quality management system.

How is the LCT implemented?

Firstly, it makes sense to discover which creases or box forming is critical to successful running in automated machinery, normally this is self-evident from issues that have occurred. Then, run some initial tests on known good and bad samples to map out the test result values and relevance of each measurement. RDM or your instrument supplier can help with this. Then potentially working with the brand owner / product packer agree these values and set an SOP for the sampling rate and recording of results. Finally, and very easily, train users to prepare and run tests.

Download the PDF version of this article HERE