ASTM, or the American Society for Testing and Materials, is an organisation that develops and publishes voluntary consensus technical standards. These standards cover a wide range of materials, products, systems, and services. ASTM standards serve as a benchmark for manufacturing, testing, and quality assurance processes across various industries. The goal is to ensure consistency, safety, and reliability in the production and use of different materials and products. Essentially, it’s a systematic approach to standardising practices for improved interoperability and quality assurance in diverse sectors.

For a selection of products that meet various ASTM standards click here.

Standard Test Method for Haze and Luminous Transmittance of Transparent Plastics

Equipment for this standard

Standard Test Method for Resistance of Transparent Plastics to Surface Abrasion by the Taber Abraser

Equipment for this standard

Standard Test Method for Linear Dimensional Changes of Nonrigid Thermoplastic Sheeting or Film at Elevated Temperature

Standard Test Method for Melt Flow Rates of Thermoplastics by Extrusion Plastometer

Equipment for this standard

Standard Test Method for Tearing Strength of Fabrics by Falling-Pendulum (Elmendorf-Type) Apparatus

Equipment for this standard

Standard Test Methods for Impact Resistance of Plastic Film by the Free-Falling Dart Method

Equipment for this standard

Standard Test Method for Thickness of Textile Materials

Equipment for this standard

Standard Test Method for Peel Resistance of Adhesives (T-Peel Test)

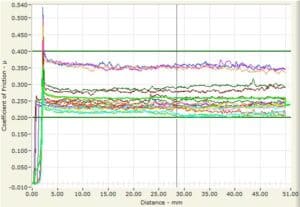

Standard Test Method for Static and Kinetic Coefficients of Friction of Plastic Film and Sheeting

Equipment for this standard

Flatbed Frictio n Testers are specialised test instruments primarily designed for testing flat sheet materials, e.g. plastic film, laminates, foils, non-wovens, carton board and paper, measuring Coefficient of Friction (COF). The instrument performs tests to ASTM D1894, ISO 8295, DIN 53375, BS2782 method 824A, TAPPI T549 and some other internationally recognised test standards.

n Testers are specialised test instruments primarily designed for testing flat sheet materials, e.g. plastic film, laminates, foils, non-wovens, carton board and paper, measuring Coefficient of Friction (COF). The instrument performs tests to ASTM D1894, ISO 8295, DIN 53375, BS2782 method 824A, TAPPI T549 and some other internationally recognised test standards.

Instruments will be fitted with a load cell to measure friction typically in the range of 0-2Kg (20N) standard, 0-5Kg (50N), or 0-10Kg (100N). The interface speed can be set typically between 1-1000 mm/min.

The RDM CF-800XS comprises a smooth horizontal flatbed (optionally interchangeable insert flatbed) with vacuum and magnetic clamps, motor drive and control system, HMI/Touchscreen, measuring load cell/encoder, and sample sled. Optional p.c. software adds possibilities for displaying, recording and printing data. Optional sample grips and fixtures extend the versatility of the system to conduct peel, tensile and tear strength test methods.

Instruments will measure and display the Static and Dynamic Coefficient of Friction, as well as Max load, Minimum load and Mean load. The instrument is available with an optional heated test bed for testing samples at temperatures up to 100 degC.

Standard Test Method for Propagation Tear Resistance of Plastic Film and Thin Sheeting by Pendulum Method

Standard Test Method for Tear-Propagation Resistance (Trouser Tear) of Plastic Film and Thin Sheeting by a Single-Tear Method

Standard Test Methods for Sampling and Testing Untreated Paper Used for Electrical Insulation

Standard Test Method for Determination of External Loading Characteristics of Plastic Pipe by Parallel-Plate Loading

Standard Test Method for Specular Gloss of Plastic Films and Solid Plastics

Equipment for this standard

Standard Test Methods for Determining the Izod Pendulum Impact Resistance of Plastics

Standard Test Method for Puncture-Propagation Tear Resistance of Plastic Film and Thin Sheeting

Standard Test Method for Column Crush Properties of Blown Thermoplastic Containers

Standard Test Method for Pressure-Sensitive Tack of Adhesives Using an Inverted Probe Machine

Standard Test Method for Determination of Leaks in Flexible Packaging by Bubble Emission

Equipment for this standard

Standard Test Method for Peel Adhesion of Pressure-Sensitive Tape

Equipment for this standard

Standard Test Methods for Thickness of Solid Electrical Insulation

Equipment for this standard

Standard Test Method for Bursting Strength of Textile Fabrics—Diaphragm Bursting Strength Tester Method

Equipment for this standard

Standard Test Method for Rheological Properties of Paste Printing and Vehicles by the Falling-Rod Viscometer

Standard Test Method for Total Energy Impact of Plastic Films By Dart Drop

Equipment for this standard

Standard Test Method for Chip Impact Strength of Plastics

Standard Test Method for Coefficient of Static Friction of Corrugated and Solid Fiberboard

Equipment for this standard

Standard Test Method for Unnotched Cantilever Beam Impact Resistance of Plastics

Standard Test Method for Coefficient of Static Friction of Uncoated Writing and Printing Paper by Use of the Inclined Plane Method

Equipment for this standard

Standard Test Method for Leakage Testing of Empty Rigid Containers by Vacuum Method

Equipment for this standard

Standard Practice for Abrasion Resistance of Printed Materials by the Sutherland Rub Tester

Equipment for this standard

Standard Test Method for Resistance to Bending of Paper and Paperboard

Equipment for this standard

Standard Test Method for Resistance to Bending of Paper of Low Bending Stiffness (Taber-Type Tester in 0 to 10 Taber Stiffness Unit Configuration)

Equipment for this standard

Standard Test Method for Surface Wettability and Absorbency of Sheeted Materials Using an Automated Contact Angle Tester

Standard Test Method for Thickness of Nonwoven Fabrics

Equipment for this standard

Standard Test Method for Corona-Treated Polymer Films Using Water Contact Angle Measurements

Standard Practice for Preparation of Cold-Rolled Steel Panels for Testing Paint, Varnish, Conversion Coatings, and Related Coating Products

Standard Test Method for Determining the Charpy Impact Resistance of Notched Specimens of Plastics

Standard Test Methods for Loop Tack

Standard Test Method for Rub Abrasion Mar Resistance of High Gloss Coatings

Equipment for this standard

Standard Test Methods for Determining the Effects of High Altitude on Packaging Systems by Vacuum Method

Equipment for this standard

Standard Guide for Determination of Thickness of Plastic Film Test Specimens

Equipment for this standard

Standard Test Method for Surface Wettability of Paper (Angle-of-Contact Method)

Methods of Test for Identification of Wire Sides of Paper

Standard Test Method for Resistance of Nonporous Paper to Passage of Air

Standard Test Method for Bursting Strength of Paper

Equipment for this standard

Method of Test for Puncture and Stiffness of Paperboard, Corrugated and Solid Fibreboard

Equipment for this standard

Standard Test Method for Tensile Properties of Thin Plastic Sheeting

Equipment for this standard

Standard Test Methods for Pressure Decay Leak Test for Flexible Packages With and Without Restraining Plates

Equipment for this standard

Standard Practice for Leaks Using Bubble Emission Techniques

Equipment for this standard

Standard Test Methods for Internal Pressurization Failure Resistance of Unrestrained Packages

Equipment for this standard

Standard Test Method for Slow Rate Penetration Resistance of Flexible Barrier Films and Laminates

Standard Test Method for Determination of Abrasion and Smudge Resistance of Images Produced from Business Copy Products (Sutherland Method)

Equipment for this standard

Standard Test Methods for Hot Seal Strength (Hot Tack) of Thermoplastic Polymers and Blends Comprising the Sealing Surfaces of Flexible Webs

Equipment for this standard

Standard Test Method for Detecting Seal Leaks in Porous Medical Packaging by Dye Penetration

Equipment for this standard

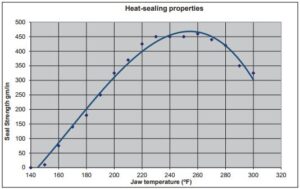

Standard Practices for Making Heat Seals for Determination of Heat sealability of Flexible Webs as Measured by Seal Strength

Equipment for this standard

Laboratory Heat Sealers are specialised test machines primarily designed for making controlled heat seals with flexible heat sealable materials e.g. plastic films, laminates, foils, and coated paper, in preparation for seal strength testing. RDM Models HS-2, HSG-3 & HSG-5 are appropriate.

The HS-2 was one of the first machines to be introduced to the market in the 1980’s, originally by British Cellophane Limited (BCL), and later by RDM Test Equipment. The machine has undergone many updates, but the principle of operation remains the same.

Depending on the model selected, the machine will be fitted with a heated upper sealing jaw, and either an unheated lower sealing bed (HS-2 Single) or a heated lower sealing bed (HS-2 Dual) with optional interchangeable sealing jaws.

The HS-2 comprises a set of sealing jaws, PID temperature controlled heating block(s) and controller(s), a pneumatic piston drive system to deliver the sealing pressure, a pressure transducer calibrated to display the sealing pressure, a precision pressure regulator for adjustment of sealing pressure, a digital dwell time controller, and a cycle time controller.

Optional sets of sealing jaws can be provided for a variety of different surface profiles (e.g. matched crimp, castle), and surface materials (e.g. brass, stainless steel, silicon rubber).

Sealing jaws are manufactured in aluminium as standard, and optionally can have a permanent Teflon coating or PTFE tape applied to reduce build-up of print/sealing material debris. The machine can be manually loaded with heat sealable film, and will produce temperature, pressure, dwell time controlled heat seals.

Standard Test Method for Burst Testing of Flexible Package Seals Using Internal Air Pressurization Within Restraining Plates

Equipment for this standard

Standard Test Methods for Pressure Decay Leak Test for Flexible Packages With and Without Restraining Plates

Equipment for this standard

Standard Test Method for Detecting Gross Leaks in Packaging by Internal Pressurization (Bubble Test)

Equipment for this standard

Standard test method for Thickness Measurement of Flexible Packaging Material

Equipment for this standard

Standard Test Method for Non destructive Detection of Leaks in Packages by Vacuum Decay Method

Equipment for this standard

Standard Practice for Determining the Scratch Hardness and Scrape Adhesion of Prints and Coatings

Equipment for this standard

Standard Practice for Abrasion and Scuff Resistance of Inkjet Media by the Sutherland Rub Tester

Equipment for this standard

Standard Test Method for Mechanical Seal Strength Testing for Round Cups and Bowl Containers with Flexible Peelable Lids

Equipment for this standard

Standard Test Method for Oxygen Gas Transmission Rate through Plastic Film and Sheeting using a Dynamic Accumulation Method

Equipment for this standard

Standard Test Method for Flex Durability of Flexible Barrier Materials

Gelbo Flex Tester

The GF-392 Gelbo Flex Tester is a specialised test machine primarily designed for flex durability testing of flexible barrier materials, e.g. plastic films, laminates, foils, and coated paper. The machine conforms to ASTM F392 and some other internationally recognised test standards.

The flex resistance of materials is determined after flex durability testing, by identifying pinhole formation or measuring other properties such as gas permeation rates. This is important to determine the resistance of different materials to flex formed pinholes and breakdown of barrier layers.

The Gelbo Flex Tester comprises two mandrels of 90mm diameter, one fixed and the other twisting and moving horizontally via a drive shaft, guide bearing and motor. The mandrels are set in a home position 180mm apart, and the test material is attached with clips to form a tube.

The moving mandrel provides a twisting action followed by a horizontal motion, which repeatedly twists and crushes the test material. The drive mechanism has two settings for long and short strokes.

The machine is controlled via an HMI keypad, by selecting the number of cycles required according to the test method/standard used. This is in the range of 2,700 cycles to 20 cycles at a constant rate of 45 cycles per minute.

On completion, the test material can be checked for pinholes by painting on a turpentine solution and identifying any marking onto a white sheet of paper, or by gas transmission rate testing.

For multi-layer structured materials, individual layers may have failures in integrity which do not present as complete pinholes, in such cases gas transmission rate testing may be useful as a measurement.

Standard Test Method for Seal Strength of Flexible Barrier Materials

Equipment for this standard

Standard Test Method for Comparison of Bond Strength or Ply Adhesion of Similar Laminates Made from Flexible Materials

Equipment for this standard

Standard Guide for Determination of Static Coefficient of Friction of Test Couples Using an Inclined Plane Testing Device

Equipment for this standard