Package testing is a critical aspect of ensuring the integrity and functionality of packaging in various industries. It involves evaluating different parameters to guarantee that the packaging effectively protects the contents and meets regulatory standards. Three essential test types – leak, creep, and burst tests – play a key role in assessing the performance and reliability of packaging materials.

Leak Test: Detecting leaks is paramount, especially in industries where maintaining the sterility, freshness, or containment of the contents is crucial. Leaks can compromise product quality and safety. Commonly used in food and pharmaceutical industries, a leak test ensures that packaging effectively prevents the entry of contaminants and preserves the product’s quality.

Creep Test: Creep testing evaluates the deformation or stretching of packaging materials over time. It is vital for assessing long-term structural integrity and stability. Particularly relevant in industries where packaging materials are subjected to prolonged stress or pressure, such as in storage or transportation. Creep tests help predict how packaging materials will behave under sustained conditions.

Burst Test: The burst test assesses the maximum pressure that packaging can withstand before rupturing. This is crucial for products that may experience internal pressure variations. Commonly used in industries dealing with pressurised or gas-filled products, such as carbonated beverages or medical devices. Ensures that packaging can withstand internal pressures without failing.

Package testing, with a specific focus on leak, creep, and burst tests, is a fundamental practice to ensure the reliability, safety, and compliance of packaging materials across diverse industries. It safeguards product quality, consumer safety, and the reputation of businesses.

If you would prefer to let us take care of your testing in the RDM LAB, simply complete the Contract Package Testing form HERE and one of our team will contact you with more information.

-

View Product

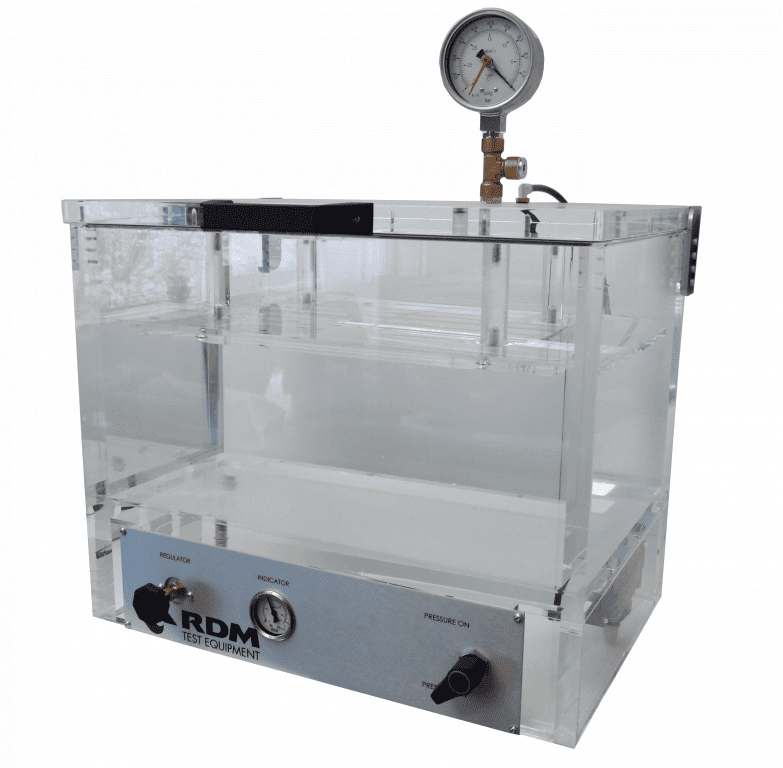

Bubble Leak Tester BLT-V

The BLT leak tester uses a regulated pressure to 850 mbar to test The integrity […] -

View Product

Bubble Leak Tester BLT-P

The BLT-P uses positive pressure via a needle / tube inserted into a pack meeting […] -

View Product

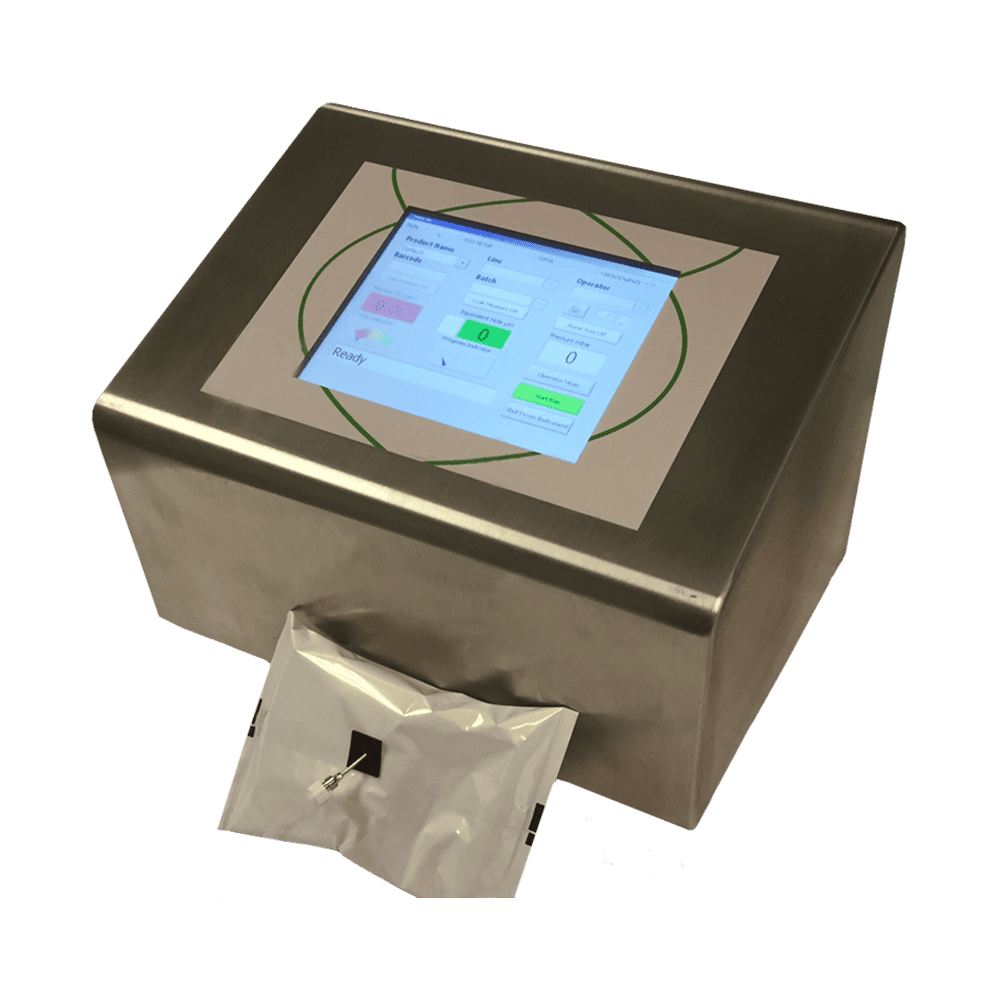

Check-A-Pack 200 Leak & Burst Package Tester

Measurement of micro leak hole size and burst pressure seal integrity with oxygen analysis, for […] -

View Product

Check-A-Pack 600 Automatic Leak and Burst Package Tester

Measurement of micro leak hole size and burst pressure seal integrity, for all flexible and […] -

View Product

Lippke® 5000

Reliable seal strength and pressure leak testing of many types of packaging. Precise, definable and […] -

View Product

Lippke® VC 1400

Vacuum leak detection system for flexible, rigid and semi-rigid packages Test seal strength and ‘whole […] -

View Product

MultiCheck 2

Reliable all-in-one headspace and leak testing system for complete MAP quality control. Trusted results Simple […] -

View Product

Stationary Leak Tester (SLT)

Oxipack’s standard solution for testing a wide range of flexible packaging, the SLT combines efficiency […] -

View Product

Stationary Leak Tester XXXL (SLT XXXL)

Designed for larger packaging up to 25 Kg, the SLT XXXL utilizes a vacuum decay […] -

View Product

Bottle Leak Tester (BLT)

The Oxipack Bottle Leak Tester is a versatile tool for detecting leaks in various bottle […] -

View Product

Can Leak Tester (CLT)

The CLT is adept at testing various can types, employing a vacuum decay method for […] -

View Product

Multi Leak Tester (MLT)

Designed to handle a variety of rigid products like pods, capsules, cans, and jars, the […]