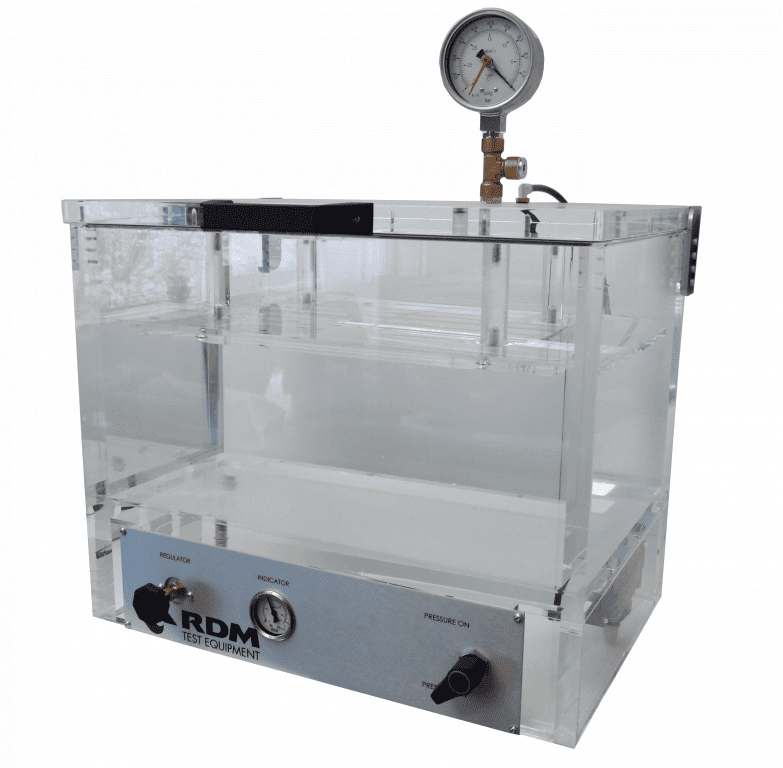

Multi Leak Tester (MLT)

Designed to handle a variety of rigid products like pods, capsules, cans, and jars, the Oxipack Multi Leak Tester employs a vacuum decay method for effective and non-destructive leak detection.

Description

The Oxipack Multi Leak Tester (MLT) offers a versatile and efficient solution for testing various rigid products like pods, capsules, cans, jars, bottles, vials, and cups. Embracing a broad spectrum of dimensions and shapes, the MLT employs the vacuum decay method for leak testing, ensuring a comprehensive assessment of the entire packaging.

Its patented FDA-approved flexible membrane is pre-formed to precisely fit the packaging, creating a minimal measuring space and a deep vacuum in the test chamber. This feature allows the MLT to adeptly detect both micro-leaks and larger leaks, maintaining the integrity of the packaging and seals. The MLT’s ability to adapt to different package sizes and filling weights makes it an invaluable tool for industries requiring high-precision leak testing, delivering direct, accurate, and non-destructive results.

Features & Benefits

Features:

- Vacuum decay method (ASTM F2338).

- Suitable for diverse rigid products like pods, capsules, cans.

- Customizable pre-formed membrane.

Benefits:

- Versatile for a wide range of packaging.

- Non-destructive and accurate leak detection.

- Fast and efficient operation with robust design.

Technical specifications

Dimensions and Weight: 465 x 305 x 330 mm (L x W x H) 10 KG

Materials: Powder coated steel, Annodized Aluminium, Polycarbonate, Onyx

Power supply: 100 – 240 VAC/kW

Air supply: > 5,5 – < 8 bar

Compliance and IP rating: IP40

Leak detection method: ASTM F2338

Air consumption: 150 Nl/min

Maximum testing capacity: 2P/M

Connections: USB/Ethernet export 24VDC logic (free programmable)

Packaging type and size: Pods, capsules, cans, jars, bottles, vials, cups