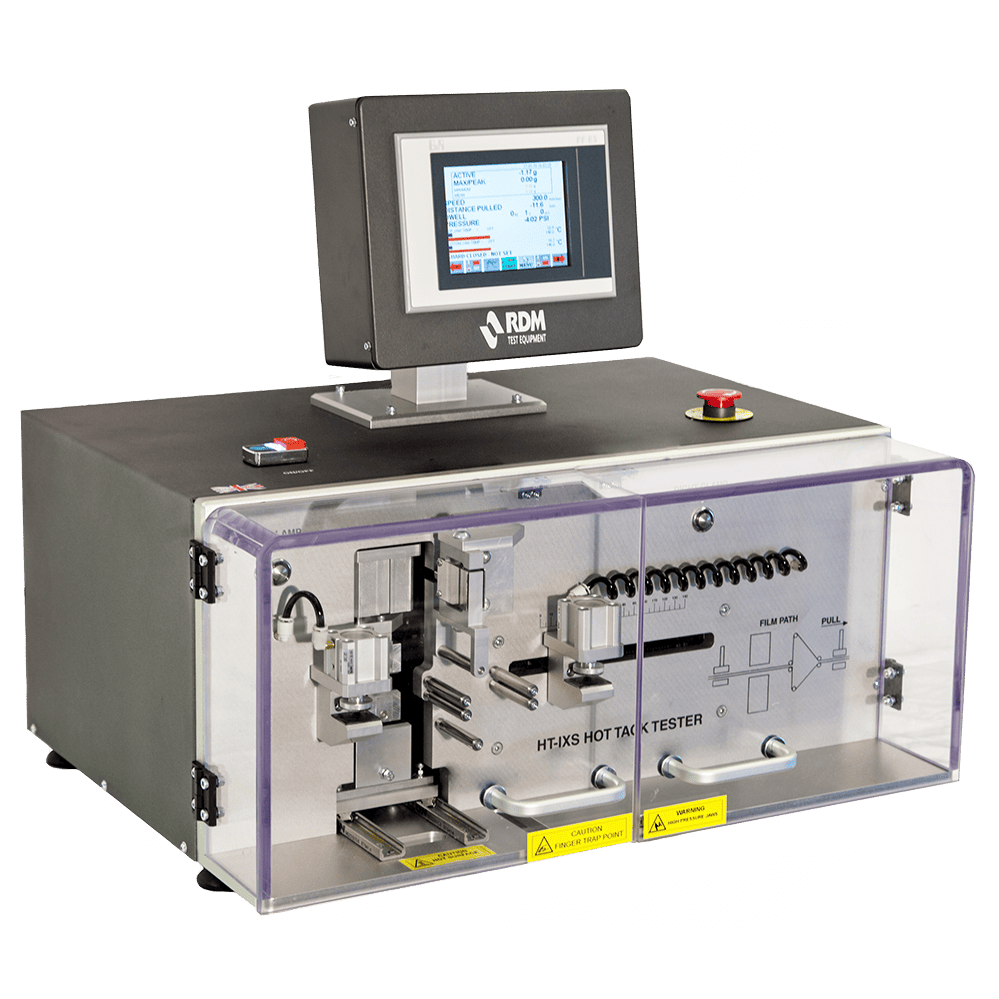

MultiCheck 2

Reliable all-in-one headspace and leak testing system for complete MAP quality control.

- Trusted results

- Simple and user friendly

- Fast and reliable

Description

By combining a headspace gas analyzer, leak detector and valve tester in one unit, the Dansensor® MultiCheck® 2 helps you achieve fast, consistent, and reliable quality control of your MAP packaging process.

Equipped with specialized filters and sensors for applications like coffee, it ensures the integrity of your MAP packaging, preserving your product’s flavor and aroma and your brand’s reputation. In addition, you can conduct integrated valve leak and valve release tests on degassing valves with the optional valve testing unit (VTU), so the integrity of your entire package is accurately tested and recorded in a combined report.

Increase the uptime of your packaging line with this reliable analyzer and avoid time consuming troubleshooting exercises when inconsistencies arise. Moreover, reduce the risk of human error and improve your quality management with dependable data storage and real time data transfer. The instrument can store test results from more than 100,000 tests.

With the ability to conduct four tests in one – headspace gas analysis, leak detection, valve leak and valve release – the Dansensor MultiCheck 2 is 50% faster, takes less space, and is more user friendly than its predecessors. It takes up less space and is more user friendly with an intuitive user interface. In addition, there are dedicated ports for the test head and VTU and USB ports for connecting additional accessories, such as a barcode scanner or keyboard. It also includes the option to conduct a burst test, to help you establish the settings and limitations for your package testing. Up to 999 product test settings can be programmed into the unit to ensure consistent test parameters.

The Dansensor MultiCheck 2 is designed for easy maintenance and cleaning, so you can proactively preserve the accuracy of your measurements and ensure uptime. Use the self-rinsing backflush program regularly to remove particles and contaminants from the system and replace the easy-to-access filters on the test head.

For additional testing options within the Lippke product line, you may consider the Lippke 5000 and the Lippke VC 1400.

Features & Benefits

Benefits

- Complete MAP quality control for coffee packaging

- Protect your brand and product

- Maximize uptime with quick and reliable package testing

- Easy to use

- All-in-one integrated solution 50% faster than previous models

- Reduce time troubleshooting issues and risk of human error

Features

- Four tests in one: headspace, leak, valve leak and valve release

- O2 headspace measurements

- Optional degassing valve test unit (VTU)

- Test head with integrated sense probe

- Easy maintenance and cleaning

- Touchscreen with intuitive interface

- Individual user logins

- Store test settings for repeatability

- Data storage and real time data transfer

- USB port for connecting optional barcode scanner, keyboard or printer

- Compliant with ASTM F2095

Technical Specifications

| Specifications | Dansensor MultiCheck 2 | |

| Test types | Headspace gas analysis; leak detection (burst and leak options); optional valve leak and valve release tests | |

| Typical test time | 60-90 seconds (combined headspace and leak test on 500 gram bag); dependent on test settings, package size, etc. | |

| Heating time (max) | 10 min | |

| Applications | Coffee (ground and whole bean) bags and packaged pillow packs | |

| Package size (max) | 5 liters | |

| Headspace analysis | Leak detection | |

| Sample volume (typical) | 25.7 ml | n/a |

| Measuring range | 0-100% O2 | 10-1000 mbar (0.15-14.5 psi) VTU mode 0-350 mbar (0-5 psi) Low range: 10-350 mbar High range: 350-1000 mbar |

| Accuracy of measurement | ±0.25% O2+ 2% of reading | Low range: ±0.5 mbar (0.007 psi) or ± 0.5% of reading High range: ±5 mbar (0.07 psi) or ± 0.5% of reading |

| Number of test definitions | 999 | |

| Data collection capacity | Test data from more than 100,000 tests | |

| Data export | Stored data to CSV file (USB) or real time data transfer CSV-string per test (RJ-45) | |

| Dimensions (WxDxH) and weight | Instrument: 304 x 236.5 x 185 mm (12” x 9.3” x 7.3”) 4.4 kg (9.7 lbs) Stand + test head: 250 x 330 x 410 mm (9.8” x 13.0” x 16.1”) 4.0 kg (8.8 lbs) | |

| Calibration and service | 12 months | |

| Ambient temperature | Operational: +2°C to +35°C Storage: -20°C to +60°C | |

| Relative humidity | Operational: 10 to 90 %RH (non-condensing) Storage: less than 95 %RH (non-condensing) | |

| Ambient pressure | Operational: 750-1100 mbar | |

| Power supply and consumption | External PSU, 100-240 VAC, 47-63 Hz Max 40W | |

| Air supply pressure and connection | 2-5 bar Ø6/4mm tube DIN ISO 8573-1:2010 [4:4:3] | |

| Air consumption | Max 5 L/min (depending on test settings) | |

| Connections | LAN: RJ-45 Ethernet 10/100 Mbit/s, DHCP client or fixed IP USB: 1 x Host, USB 2.0 Type A; 1 x Device, USB 2.0 Type B (max current 500 mA) | |

| Consumables and accessories | Septa, VTU (valve test unit) | |

| Warranty | 12 months | |

| Compliance | CE, China RoHS II | |

| Standards | ASTM F2095, ISO 11607 | |

Accessories

Accessories

- Integratable Valve test unit (VTU)

- Barcode scanner with USB connector

- Keyboard with USB connector

Consumable

- Septa

Service & Support Options

- PTPS AMECare Program

Applications

Applications

- Complete MAP quality control of coffee packaging – whole bean and ground, pillow packs and bags (not capsules)

- Up to four tests in one: headspace gas analysis, leak detection, valve leak and valve release

- Burst test for finding package limits and establishing settings

Standards

- ASTM F2095 (Standard Test Methods for Pressure Decay Leak Test for Flexible Packages)