RDM Laboratory Heat Sealers play a crucial role in enhancing the quality of your sealing processes. Designed to meet various sealing needs, our range includes basic sealers, touch-screen controlled semi-automated production sealers, and customisable designs. Drawing from our extensive experience, we aim to assist in optimising your heat sealing operations.

These Laboratory Heat Sealers are suitable for packaging diverse items such as flexible pouches, lidded trays, and pots of all sizes. Optional features like gas flush and/or vacuum further contribute to their adaptability, making them suitable for applications in the lab, pilot plant, or small-volume manual production environments.

Notably, our heat sealers come with options for Single or Dual heated sealing jaws, and for added durability, you can opt for a permanent Teflon coating. This adaptability ensures that our heat sealers can accommodate a range of sealing requirements without compromising precision.

Whether you are dealing with standard sealing procedures or have specific needs, our aim is to provide insights into the functionalities and capabilities of RDM Heat Sealers, aiding you in making informed decisions based on your unique requirements.

To read more about Heat Seal Testing, you can find our Heat Seal Parameters of Flexible Polymer Film and Finished Package Seal Integrity – Quality Control inspection issues white paper HERE.

If you would prefer to let us take care of your testing in the RDM LAB, simply complete the Heat Seal and Hot Tack Testing form HERE and one of our team will contact you with more information.

- View Product

HSE-3 Laboratory Heat Sealer

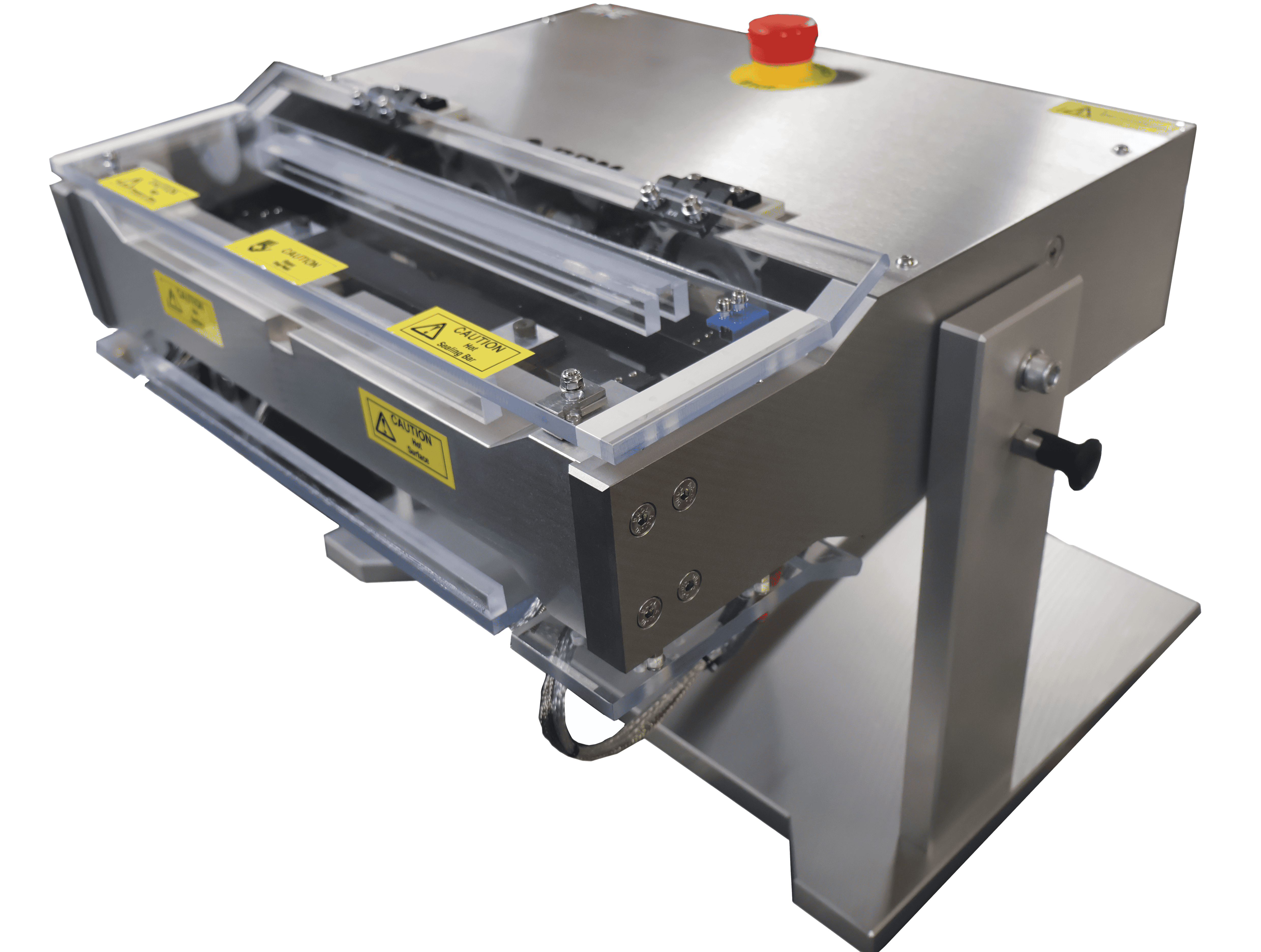

For production of high quality heat seals and/or precise measurement of heat sealability of flexible […] - View Product

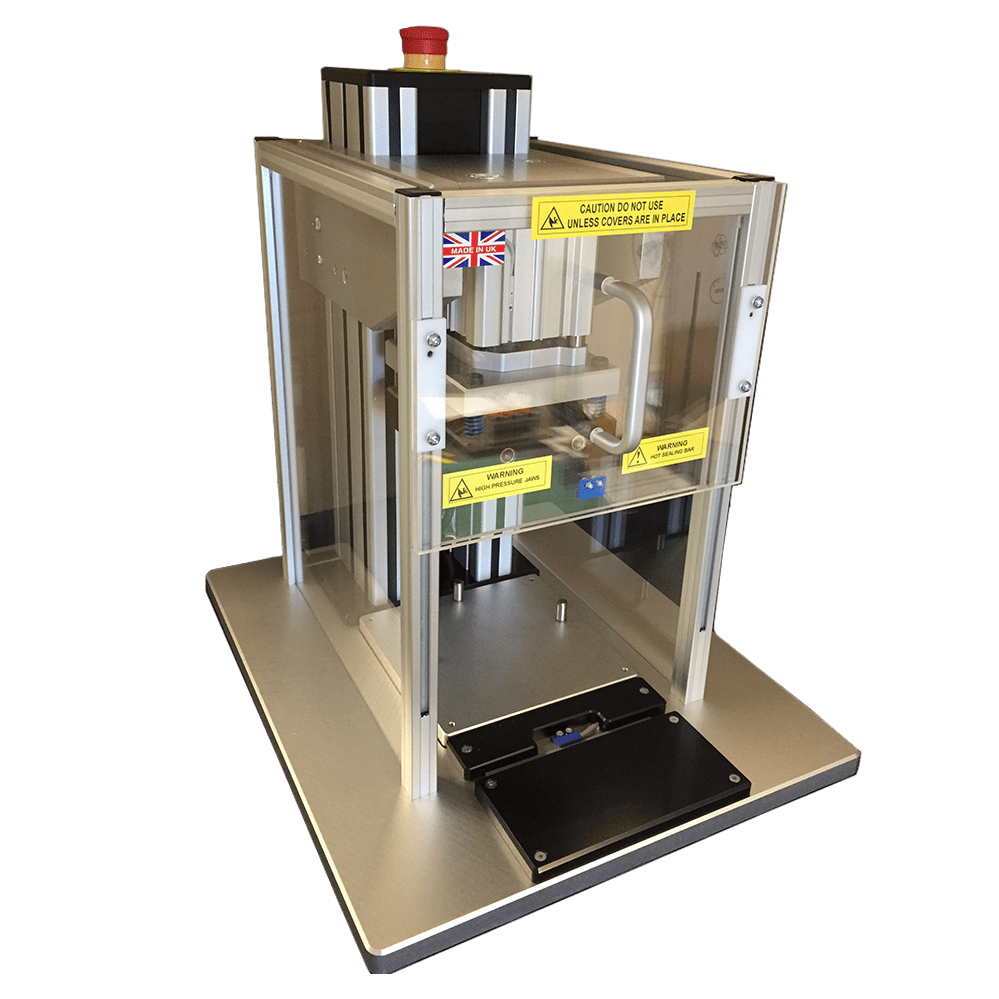

HSE-3 Vertical Heat Sealer

HSE-3 Vertical Sealing Unit with Adjustable Loading Positions Engineered for flexibility and precision, the HSE-3 […] - View Product

HSB-1 Laboratory Heat Sealer

For production of heat seals and/or measurement of heat sealability of flexible packaging. Produces seals […] - View Product

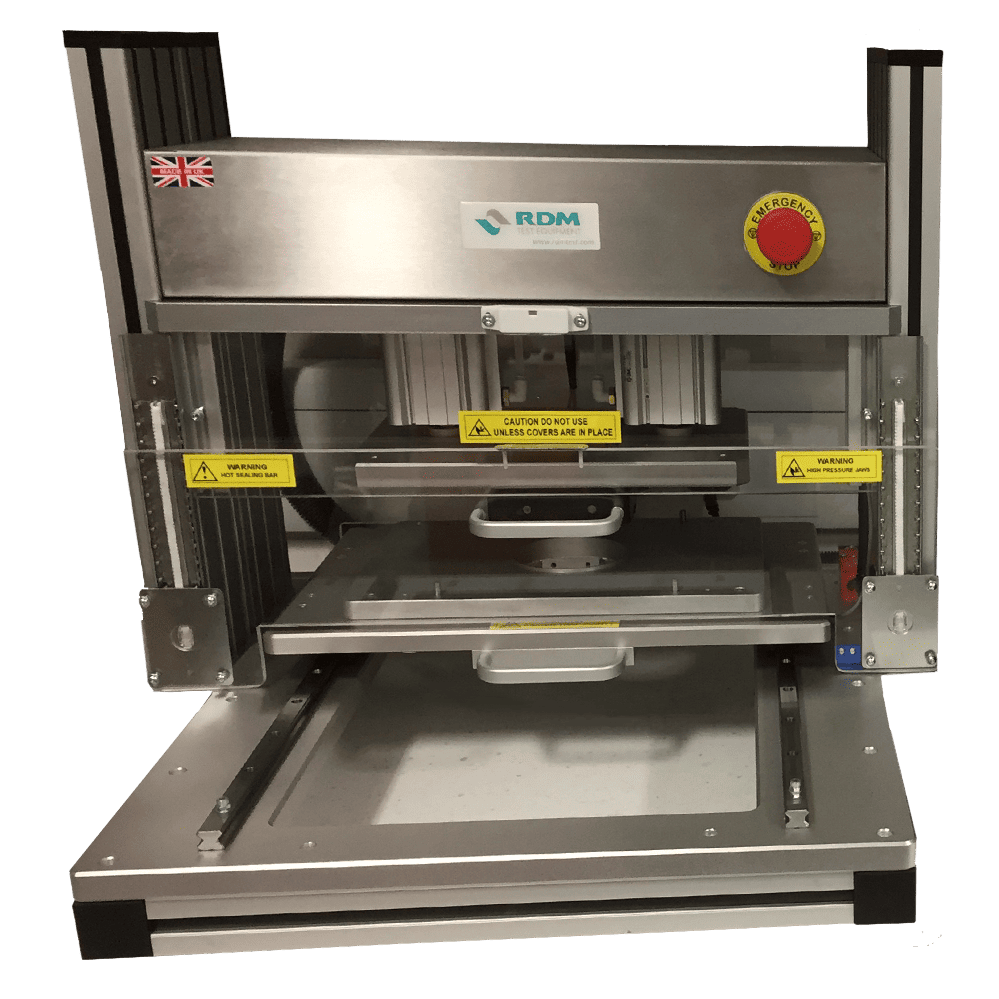

HSP-1 Tray Sealer

For lab scale / prototype production of repeatable high quality heat seals in pot / […] - View Product

HSP-2 Tray Sealer

For lab scale / prototype production of repeatable high quality heat seals in tray lidding […] - View Product

TS-1 Tray Sealer

Production of high quality heat seals, for lidding films on trays, containers, pods, and blister […]

RDM’s Laboratory & Production Heat Sealers have set the standard in precision and reliability for over 30 years. All RDM Heat Sealers are manufactured in UK, conform to ASTM F2029, and meet our stringent quality checks.

Laboratory Heat Sealers offer precise control of jaw temperature, pressure and dwell time enabling accurate determination of Heat Sealability. Setting these variables incorrectly in production is a costly business in immediate waste, spoilage and customer returns. The custom-made nature of modern flexible films, foils, coated papers and non wovens makes it vital to regularly check the heat sealing characteristics of every batch.

Medical / Production Heat Sealers provide flexibility and control dependent on your requirements. With a range of basic units through to our industrially designed semi-automated production units, and bespoke designs to meet your special requirements, we offer our experience and expertise to help you achieve better sealing quality. To browse our range of Medical Heat Sealers click HERE.

Tray Heat Sealers enable small scale production of finished packs with a flexible lidding film for trays, blister packs, pots, capsules, pods, vials etc.

Selection Guide – Browse our standard units above or call us to discuss your needs. Choose from three user interface designs, (Touchscreen, Digital or Dial Gauge), and options in sealing bar design (e.g. flat metal to silicon rubber, metal to metal, metal crimp). We also manufacture adaptations for any special requirements.