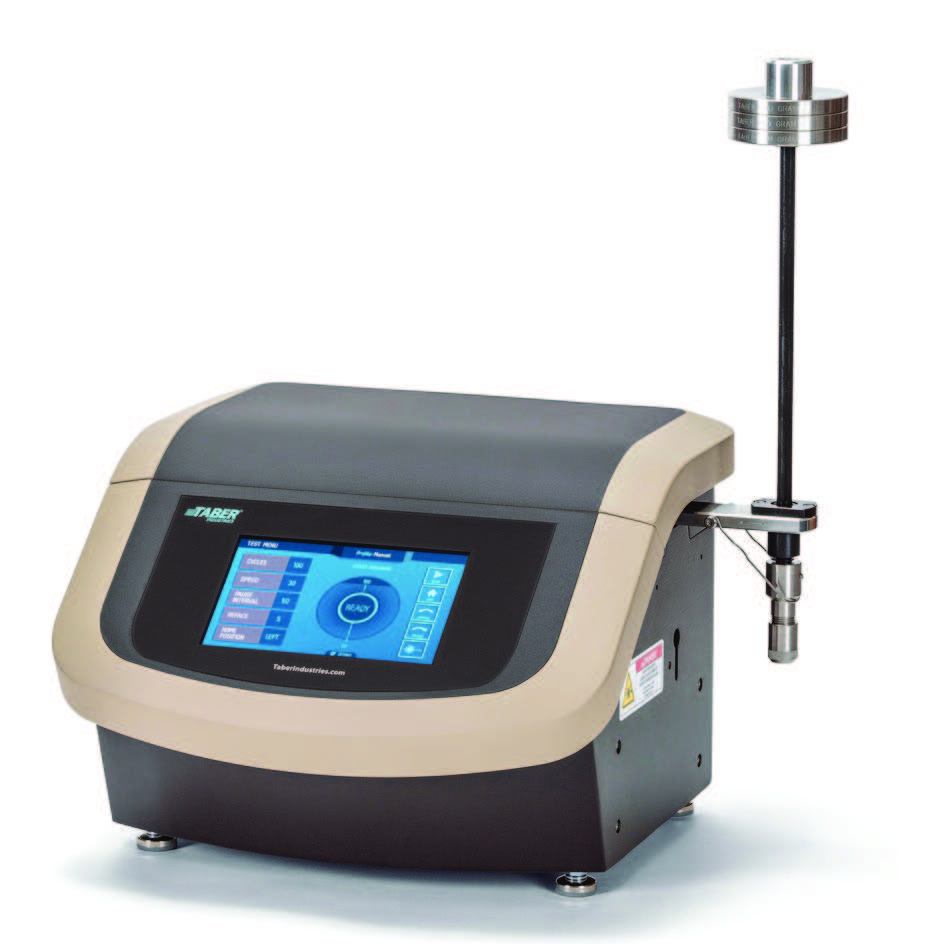

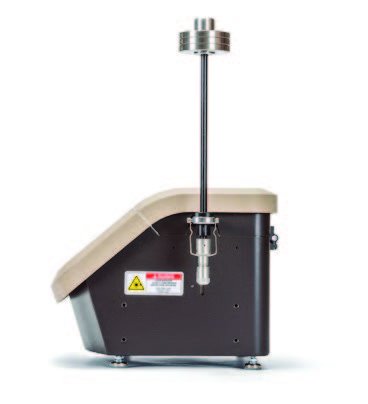

Taber 5770 Linear Abraser

The Taber 5770 Linear Abraser is a versatile, precision instrument designed to test abrasion, wear, and surface damage on both flat and contoured materials.

Description

Engineered for quality and reliability, the Taber 5770 Linear Abraser provides an advanced solution for evaluating surface durability. It uses a precision spline shaft with a free-floating test system that follows the contours of your specimen. With adjustable stroke length, speed, and load, the Linear Abraser allows you to replicate real-world wear conditions on a variety of materials. A large selection of test attachments and standardized abrasives makes it ideal for testing abrasion, scratch, mar, gouge, rub, and other surface damage, in both wet and dry conditions.

Features & Benefits

Key Features

LCD Touchscreen Interface – Simple setup with selectable display options.

Adjustable Stroke Length – Eleven standard stroke lengths from 0.2 to 4 inches.

Variable Test Speed – 2 to 75 cycles per minute for flexible test conditions.

Wide Load Range – 350 to 2,400 grams with optional auxiliary weights.

Laser Alignment Guide – Accurate specimen positioning every time.

Safety Interlock – Stops test automatically when lid is raised.

Configurable Attachments – Perform abrasion, scratch, mar, rub, gouge, and more.

Wet or Dry Testing – Supports a wide range of test conditions.

Durable Construction – Designed for long-term, repeatable testing in lab or production environments.

Benefits

Test Versatility – One instrument for multiple surface durability tests.

Replicate Real-World Conditions – Adjustable stroke, speed, and load for realistic testing scenarios.

High Accuracy & Consistency – Laser alignment and precision mechanics ensure repeatable results.

Compliance with Standards – Use with Taber standardized abrasives for recognized testing protocols.

Easy Operation – LCD touchscreen, home feature, and quick-change attachments streamline testing.

Technical Specifications

| Specification | Details |

|---|---|

| Stroke Lengths | 11 standard lengths from 0.2 to 4.0 inches |

| Stroke Speed | Adjustable 2 to 75 cycles per minute |

| Load Range | 350 g to 2,400 g with auxiliary weights |

| Test Surface | Flat or contoured specimens |

| Laser Alignment Guide | For precise sample positioning |

| Testing Modes | Wear, abrasion, scratch, mar, rub, gouge, and more (wet or dry) |

| Dimensions (approx.) | 13.6 in x 17.8 in x 20 in (345 mm x 453 mm x 508 mm) |

| Standard Accessories | Wearaser Collet Kit, Stainless Steel; 250g Weight Discs (x3); CS-10 & H-18 Wearasers; Wearaser Depth Gauge/Sharpener; Refacing Strips; Hand Brush |

Accessories

Optional Accessories

Wide selection of standardized Taber abrasives

Accessory weight discs

Specimen mounting options

Wear & abrasion test attachments

Scratch & mar test attachments

Wire / cable scrape abrasion kit

Flexible film abrasion kit

Optional T-Slot Specimen Table (for securing most test specimens)