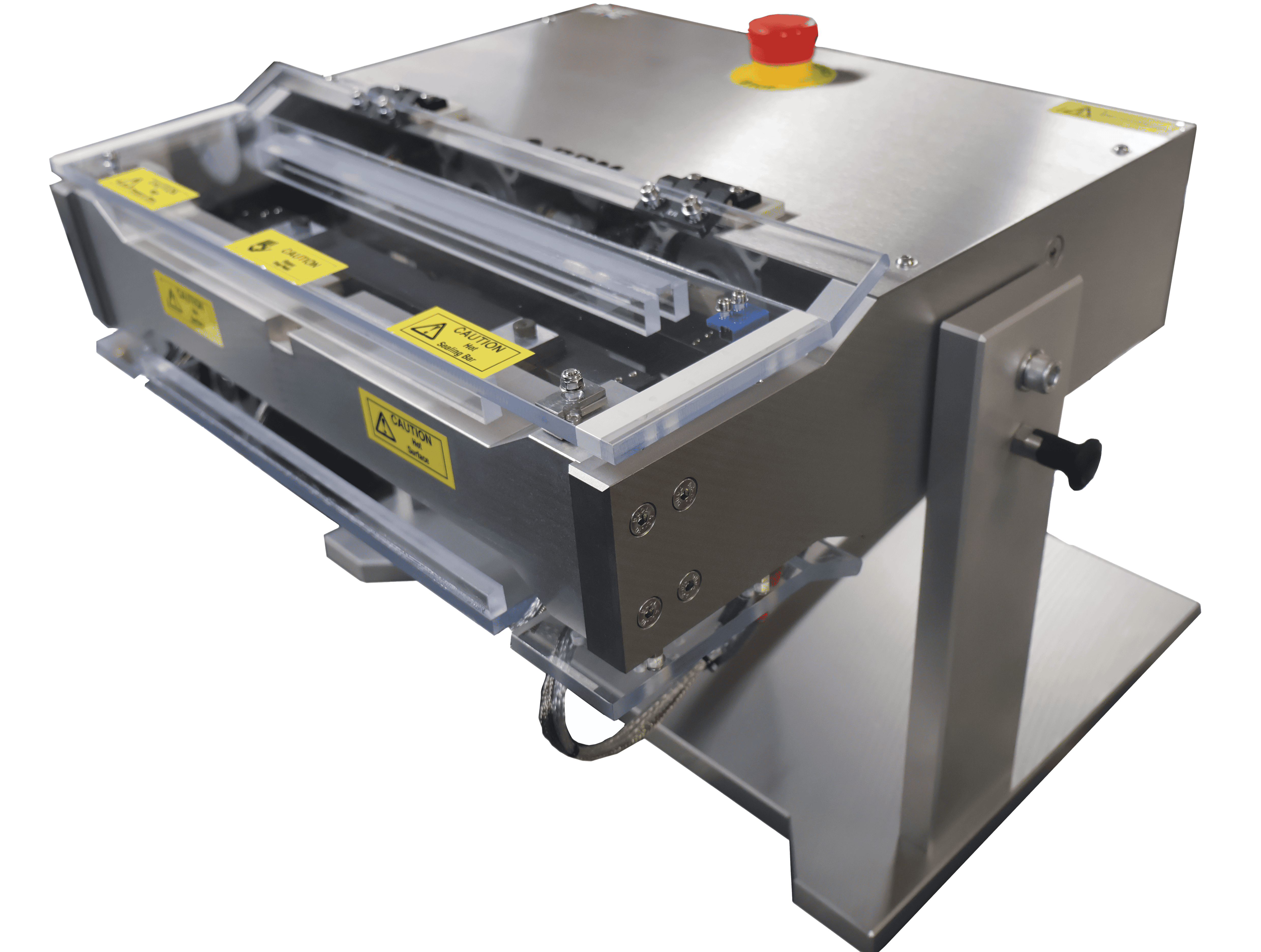

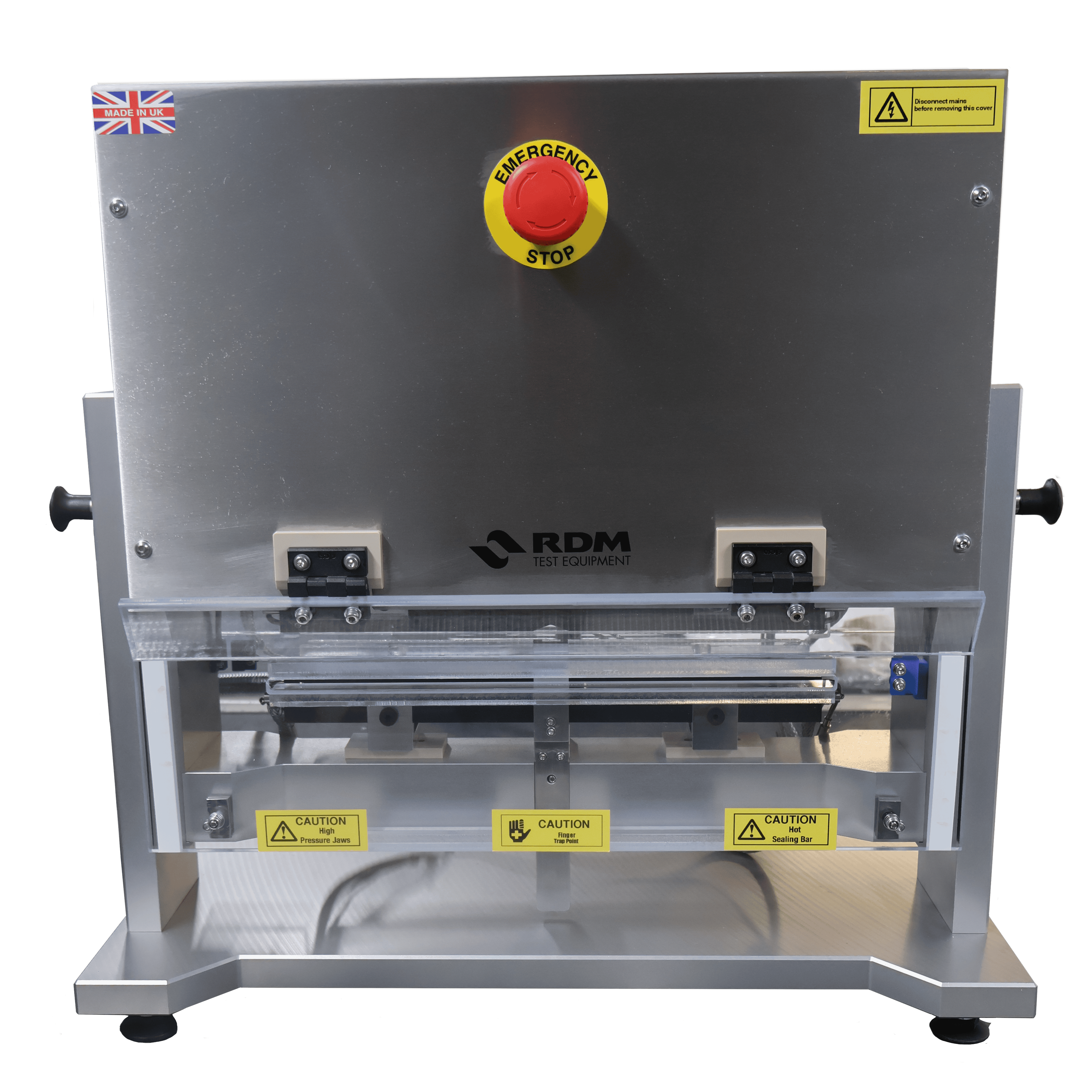

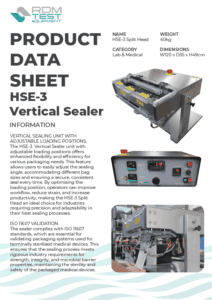

HSE-3 Vertical Heat Sealer

HSE-3 Vertical Sealing Unit with Adjustable Loading Positions

Engineered for flexibility and precision, the HSE-3 Vertical Sealer features adjustable loading positions to accommodate a wide range of bag sizes and sealing angles. This ergonomic design enhances workflow, reduces operator strain, and ensures consistent, secure seals—ideal for demanding packaging environments. Fully compliant with ISO 11607, the HSE-3 meets critical validation standards for sterile medical packaging, ensuring strength and integrity.

Description

VERTICAL SEALING UNIT WITH ADJUSTABLE LOADING POSITIONS.

The HSE-3 Vertical Heat Sealer unit with adjustable loading positions offers enhanced flexibility and efficiency for various packaging needs. This feature allows users to easily adjust the sealing angle, accommodating different bag sizes and ensuring a secure, consistent seal every time. By optimising the loading position, operators can improve workflow, reduce strain, and increase productivity, making the HSE-3 Vertical Heat Sealer an ideal choice for industries requiring precision and adaptability in their heat sealing processes.

ISO 11607 VALIDATION

The sealer complies with ISO 11607 standards, which are essential for validating packaging systems used for terminally sterilised medical devices. This ensures that the sealing process meets rigorous industry requirements for strength, integrity, and microbial barrier properties, maintaining the sterility and safety of the packaged medical devices.

Features & Benefits

FEATURES:

1. Pressure calibration of standard surface area jaw face.

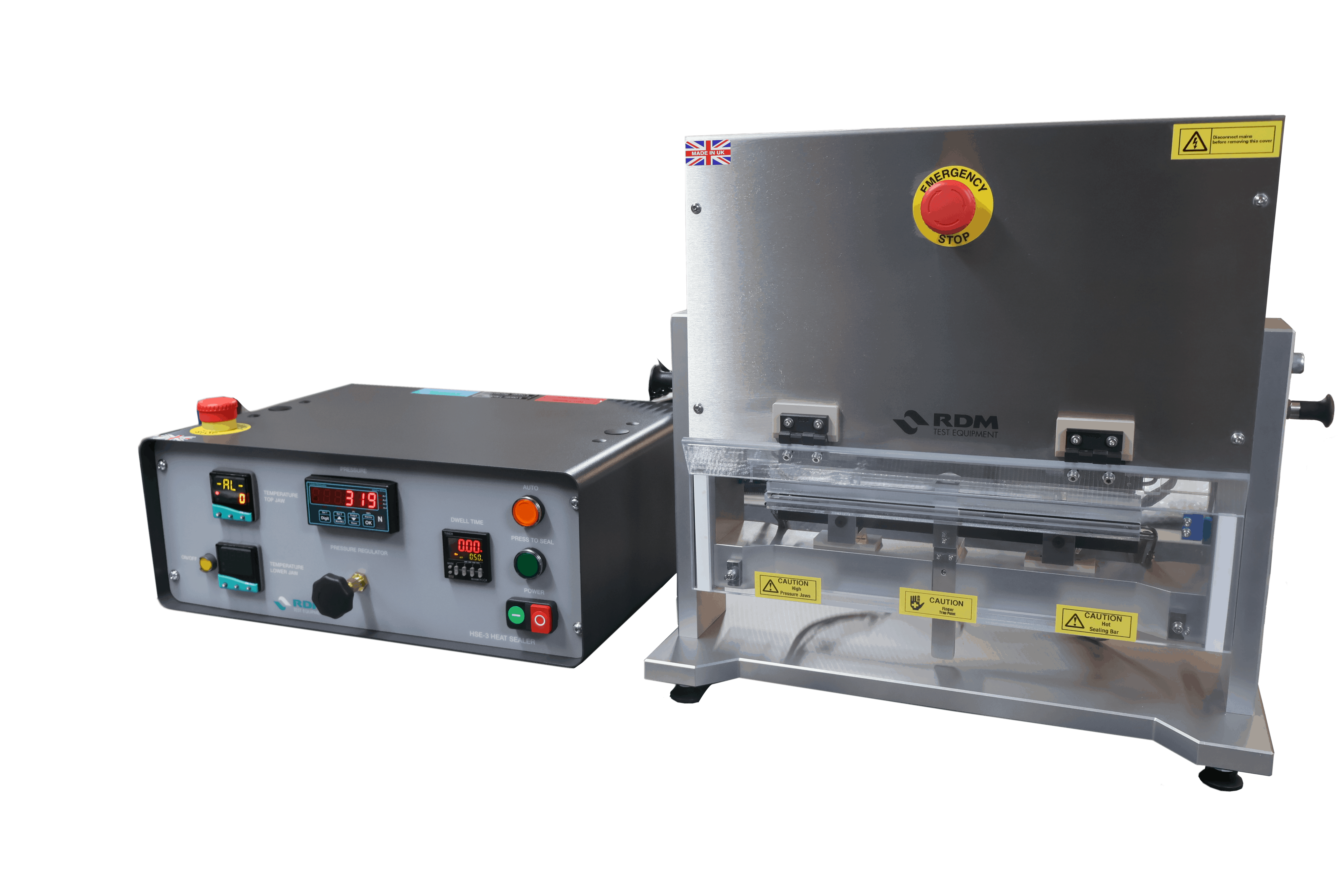

2. Temperature, pressure and dwell time dial controls.

3. Range of jaw face surfaces including Matched Crimp and Teflon Coating.

4. Auto cycle feature for greater user convenience with multiple samples

5. Split unit for mechanical rotation and storage availability.

BENEFITS:

1. Choose heat sealing bar Configuration, either single (upper) or dual (upper & lower) meets ASTM F2029.

2. User can easily change sealing bar for various surface areas or surface finishes.

3. Accurate and repeatable seals due to precision ground sealing faces and advanced jaw guidance system.

4. Versatile applications for flexible materials, porous and non-porous films, foils and blister packs.

5. Low Maintenance – 12 months between calibrations

Technical Specifications

SPECIFICATION

MODELS: Single—Upper jaw temperature controlled. Dual—Upper and Lower jaw temperature controlled.

SEAL (WxL): Standard 300 x 25 mm. (Option to extend to 350 x 25mm).

TEMP. CONTROL: Ambient to 300°C, Accuracy: +/- 0.5%, Operating Accuracy: +/-2°C. Single (Upper) sealing jaw

temperature control, or Dual (Upper & Lower) sealing jaw temperature control.

PRESSURE: Range: 0 to 100psi (6.8bar, 689Kpa), via precision regulator and digital display. Accuracy +/-5%,

Repeatability +/- 0.02psi. Supply via clean and dry compressed airline or bottled air/nitrogen at 90 to 100psi.

DWELL TIME: 0.1 to 99.9 sec. Resolution 0.1 sec.

DELAY TIME & AUTO CYCLE:: 0.1 to 99.9 sec For automatic cycling of sealing bars used in manual production environments. Assists with correct alignment of sample. Electronic processor controlled.

JAW GUIDANCE: Fitting to suit customer application.

SEALING JAWS: Standard flat jaws 25mm x 300mm, constructed in aluminium with precision ground face. Lower

sealing jaw with precision ground silicone rubber face.

ENVIRONMENT: 240V AC 50/60 Hz (110V AC available on request).

POWER: 5-50°C ambient operating temperature, RH 75% max (non-condensing).

Accessories

OPTIONS AND CUSTOMISATION

SEALING JAW DIMENSION/PROFILE

Customisable jaw dimensions and profiles, including a matched crimp (120° x 1.8mm pitch), for optimal sealing on different materials.

TEFLON COATED TAPE OR JAWS

Non-stick Teflon coating prevents materials from sticking, with options for replaceable tape or permanent coated jaws for low-maintenance operation.

BLISTER PACK SIMULATOR SEALING JAW

Providing precise and reliable seals for blister packs, ensuring consistent sealing quality and material compatibility, making it ideal for medical packaging.

FOOT SWITCH

Allowing hands-free operation for increased efficiency and ease during sealing. This feature ensures precise control while maintaining workflow continuity.

CUSTOM LOADING SYSTEMS

For seamless integration into various production setups. This enhances efficiency and ensures consistent positioning for accurate sealing.

INTERLOCKED GUARDS

For enhanced safety, preventing operation when access panels are open. This ensures user protection without compromising efficiency.