Coefficient of Friction Testing Equipment (COF) is crucial in determining how materials interact during sliding, both with themselves and with different surfaces. In the packaging industry, Coefficient of Friction testing equipment is essential to ensure materials have the right properties for seamless operation on automatic production lines and stability during transportation.

Friction properties can vary based on material composition, additives like slip agents, temperature, humidity, and aging. By testing these factors, you can optimise your packaging design for efficient production, handling, storage, and stacking. The result? Superior quality and significant cost savings.

Test methods are defined by standards such as ASTM D1894, ISO 8295, BS 2782 and TAPPI T549. Within ASTM D1894, properties are specified for sample dimensions, conditioning, accuracy of measurement and sliding speed. These properties help to ensure repeatability and reproducibility.

To read more about Coefficient of Friction Testing, you can find our Definition and Measurement of Co-efficient of Friction white paper HERE.

If you would prefer to let us take care of your testing in the RDM LAB, simply complete the Contract Friction Testing form HERE and one of our team will contact you with more information.

- View Product

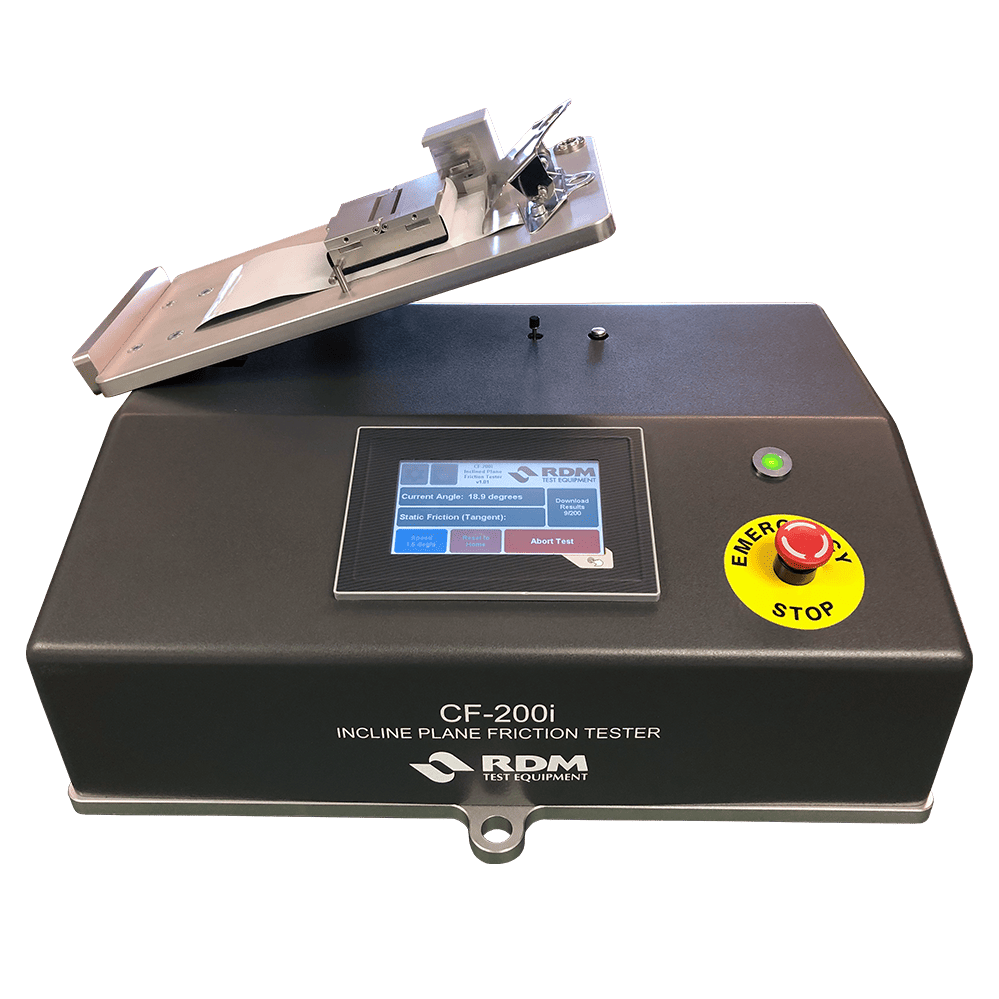

CF-200i Inclined Plane Coefficient of Friction Tester

The CF-200i Inclined Plane Co-efficient of Friction Tester determines the static friction properties of plastic […] - View Product

CF-400 Precision Friction Tester

Touch Screen Precision Friction Tester for determining Static and Kinetic Friction of packaging materials to […] - View Product

CF-800XS Precision Friction Tester

Touch Screen Precision Friction Tester for determining Static and Kinetic Friction of packaging materials to […]

What Is the difference between Static and Dynamic friction tests?

Friction is the force needed to start sliding an object (Static Friction), or the force needed to keep it sliding (Kinetic Friction), expressed as a ratio by dividing into the downward force of the mass. RDM Friction testers enable users to perform Static and Dynamic Friction tests, as well as measuring Max load, Minimum load and Mean load.

Which slip test equipment is best for your application?

There are commonly 3 types of test method known as direct flat bed (horizontal bed), inclined plane, and universal test machine with friction testing attachment. Each have their advantages and disadvantages, with the direct flat bed method being the gold standard for repeatability and reproducibility. RDM application engineers can help you to select the most appropriate slip test equipment.

To learn more about Friction testing check out What is Co-efficient of Friction?