We provide Contract testing of packaging materials via our RDM LAB. Equipped with many of the products needed to cover all packaging and materials testing, including brands such as RDM, AMETEK MOCON, DANSENSOR, and TMI, it provides flexibility and a cost effective solution for individual projects or on-going quality control.

Permeation testing

Oxygen, water vapour or carbon dioxide, Mocon permeation testing for films and packages.

Permeation testing is a method used to assess how gases or vapors can pass through materials. It’s crucial for industries where maintaining barriers against moisture, odors, or chemicals is important. This testing involves measuring the rate at which these substances permeate through substances like polymers, fabrics, or membranes. It helps in determining the effectiveness of these materials as barriers and is commonly used in fields like food packaging and medical devices to ensure product quality and safety.

If you are looking to purchase Permeation Testing Equipment please click here

Heat Seal Testing

Laboratory heat sealing, Seal strength testing and Hot tack testing of heat sealable materials.

Heat seal testing is a method used to assess the strength and integrity of seals formed between materials using heat. It’s crucial in packaging industries to ensure products remain properly sealed during handling, transportation, and storage. The test subjects seal samples to controlled temperature and pressure conditions to simulate real-world scenarios and determine their ability to withstand stress.

If you are looking to purchase Heat Seal Testing Equipment please click here

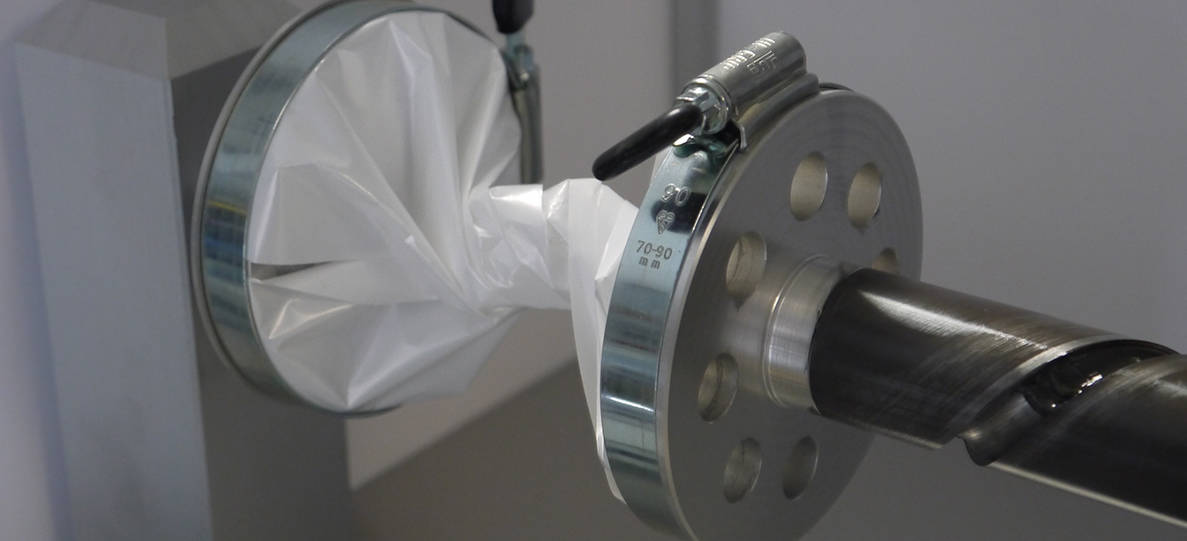

Package Integrity Testing

Leek, creep and burst testing of finished packaging such as food and medical item pouches.

Leak testing verifies the integrity of seals to prevent unintended substance leakage. Creep testing evaluates how materials deform under constant stress over time, crucial for durability assessments. Burst testing determines the maximum pressure a component can withstand before failure, ensuring safety and reliability. These tests, collectively known as Package Integrity Testing, contribute to product quality, reliability, and safety across various industries.

If you are looking to purchase Package Integrity Test Equipment please click here

Friction Testing

Measuring slip of flat materials such as packaging films.

In the packaging industry, coefficient of friction (COF) testing ensures that packaging materials have the right slip and grip balance. It measures how smoothly materials slide on manufacturing equipment and how much friction they provide to prevent slippage during transportation and stacking. This testing helps optimize packaging designs, ensuring efficient production, easy handling, and secure stacking, ultimately improving product quality and reducing costs.

If you are looking to purchase Friction Testing Equipment please click here

Physical Testing

Tensile, Crush, Bending, Tear, Impact and Penetration of all flexible materials and packages.

In the packaging industry, various tests ensure materials meet quality standards for durability and protection. Tensile testing measures strength, crush testing assesses compression resistance, and bending testing checks flexibility. Tear testing evaluates resistance to tearing, while impact testing assesses resilience to shocks. Penetration testing ensures puncture resistance against sharp objects. These tests, collectively known as Physical Testing, guarantee packaging materials meet rigorous standards for performance and reliability.

If you are looking to purchase Physical Testing Equipment please click here

Surface And Optical Testing

Haze, Clarity, Opacity, Gloss and Transmittance of flat materials.

In the packaging industry, optical and surface testing ensure materials meet quality standards. Surface testing assesses texture and appearance, vital for aesthetics and functionality. Optical testing, including haze, clarity, transmittance, and gloss testing, evaluates visual properties. Haze testing measures cloudiness, crucial for transparency. Clarity testing assesses transparency, while transmittance measures light passage. Gloss testing evaluates reflectivity, enhancing aesthetic appeal. Together, these tests ensure packaging materials meet standards, enhancing product presentation and consumer satisfaction.

If you are looking to purchase Surface and Optical Test Equipment please click here