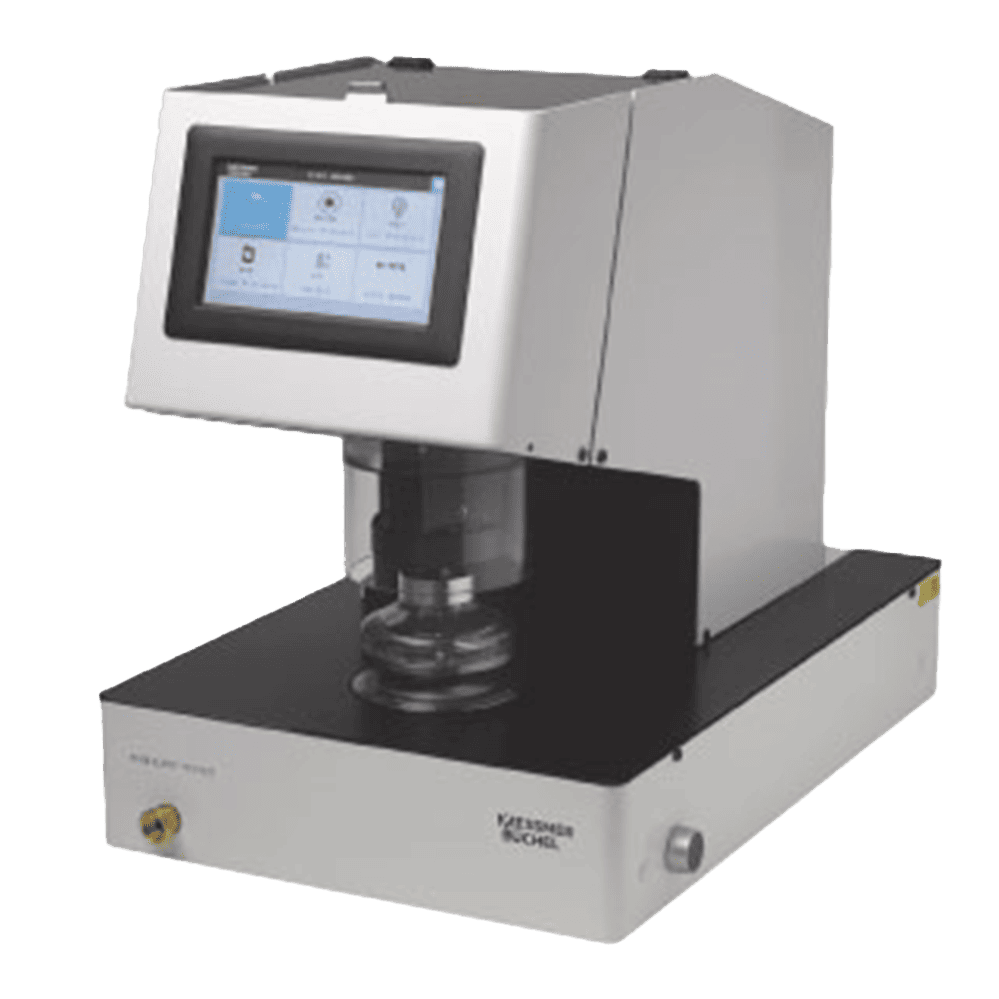

13-56 Burst Tester

The new and improved 13-56 Burst Tester has been designed for burst and leak testing on Flexible Packaging, such as paper, foils, paper boards, corrugated board, textiles etc

Description

Digital Mullen-style burst testers allow you measure the strength and resilience of sheet materials by testing for real life failures such as punctures and rupture. The technique uses hydraulic pressurization of a membrane against a clamped, film, or sheet sample, producing a multi-directional stress on the material to failure – which is the burst strength. Depending on the type of material being tested, the burst method highlights the planar strength of the sample and is sensitive to quality of fiber bond, interlaminar, or orientational defects of your sheet product. With improved electronics and a state-of-the-art user interface, our new 13-56 burst tester is easier to use than ever before. Your sample is pneumatically clamped, and the rubber membrane is pushed upwards by digitally controlled hydraulics. The force at burst is displayed and recorded automatically and can be incorporated into on-board batch analysis if desired. All aspects of the test method are easily adjustable – allowing you to create the perfect testing conditions for each unique application.

You can use the instrument to test papers and paperboards, corrugated, polymer films and laminates, or textiles. We provide different models customised for these applications to suit a range of pressure levels that offer more accurate results. You can use the 13-56 on any suitable sheet or film product within the pressure range of the instrument. If you’re unsure whether the 13-56 can be used on your chosen application, just get in touch and we’ll be happy to offer you more information.

Features & Benefits

- Features & Benefits:

- State-of-the-art on-board electronics and control software – including a large color LDC touchscreen display.

- Improved user interface that allows both standard and customized tests to be easily stored and re-called.

- Large and easy-to-understand icon driven menu screens – making it easy to configure to the latest to international standards

- New optional laser gauge that measures bubble height (required by select textile industry standards)

- Digital Mullen-style burst testers allow you measure the strength and resilience of sheet materials by testing for real life failures such as punctures and rupture

Technical Specifications

Models: 13-56-00-0001, 13-56-00-0002, 13-56-00-0003, 13-56-00-0004 Low, Medium and High pressure configurations available

Max Measuring Pressure: 2,000kPa (290psi), 5000kPa (725psi), 7000kPa (1015psi

Dimensions: 559mm x 375mm x 483mm (22” X 14.75”x 19” H)

Weight: 60 kg (132 lbs.)

Electrical: Universal (110-230 VAC, 50/60Hz)

Air: Instrument quality 600kPa (6 bars)

Safety: One button start available when safety hood engaged. Two button operation is required if the safety hood is not engaged.

Options: Laser Height Gauge Assembly available to measure peak deflection, per ISO 13938-1 and related international standards. Must be purchased with 13-56 unit at time of original order. GraphMasterPro™ PC based data collection and curve analysis software.

Serial Printer for direct export of data and analysis from 13-56 tester (no PC required).

Note: Model 13-56-00-0004 available with 7.3cm2 diaphragm

Standards

- ISO 2758

- ISO 2759

- ISO 13938-1

- ASTM D 3786

- BS 3137

- EDANA NWSP 30.1

- EDANA NWSP 30.2

- TAPPI T403

- TAPPI T807

- TAPPI T810

- FEFCO 4

- SCAN P24

- SCAN P25

Applications

Perfect for all sheet materials

You can use the instrument to test papers and paperboards, corrugated, polymer films and laminates, or textiles. We provide different models customised for these applications to suit a range of pressure levels that offer more accurate results. You can use the 13-56 on any suitable sheet or film product within the pressure range of the instrument.