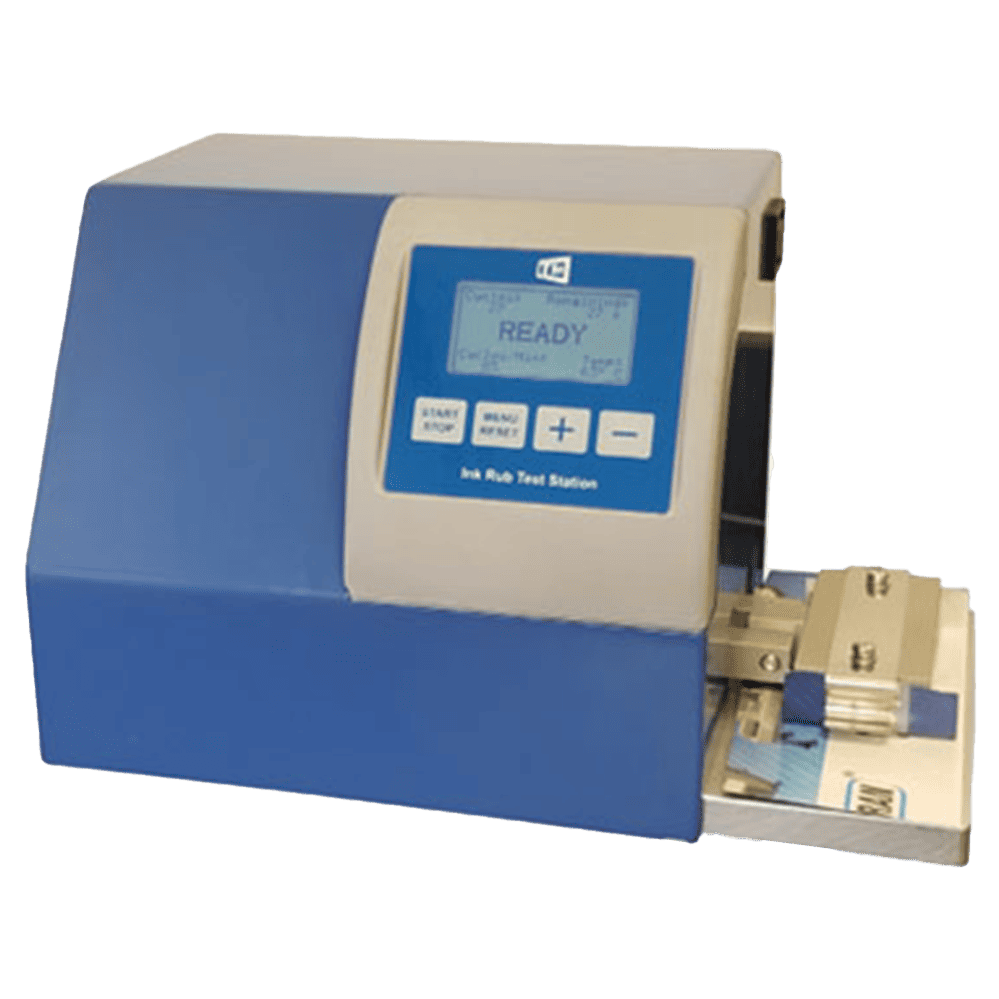

TMI 10-20 Digital Ink Rub Tester

The Digital Ink Rub Tester is designed to measure scuffing or rubbing resistance.

The Digital Ink Rub Tester is designed to measure scuffing or rubbing resistance. Several tests can be performed including dry rub-the amount of transfer ink from one dry surface to another, wet rub-the amount of transfer of ink from wetted surface to another, wet bleed or transfer-ink transfer to a water-saturated blotter, wet smear-similar to wet bleed with the addition or rub cycles, functional rub/wet rub-smear or transfer tests using a liquid other than water and hot abrasion. An optional heated weight provides a uniform test for evaluating “hot abrasion” resistance of printed cartons, labels etc.

Superceeds TMI Model 10-18 Digital Ink Rub Tester.

Description

The Digital Ink Rub Tester using ASTM D5264 and is designed to measure scuffing or ink rub resistance.

Several tests can be performed including dry rub (the amount of transfer ink from one dry surface to another), wet rub (the amount of transfer of ink from wetted surface to another), wet bleed or transfer (ink transfer to a water-saturated blotter), wet smear (similar to wet bleed with the addition or rub cycles), functional rub/wet rub (smear or transfer tests using a liquid other than water and hot abrasion).

An optional heated weight provides the 10-20 Rub Resistance Tester with a uniform test for evaluating hot abrasion resistance of printed materials like fabric, plastics.

Scuff resistance

Scuff resistance refers to a material’s ability to withstand surface damage or marking when subjected to frictional forces or contact with other surfaces during everyday use.

It measures the capacity of a material to resist marks, abrasions, or superficial damage caused by rubbing, scraping, or contact with another object or surface, often indicating its durability and resilience in maintaining its appearance over time against such interactions.

Materials with high scuff resistance tend to retain their original appearance and structural integrity despite repeated friction or contact. Testing scuff resistance involves assessing how well a material withstands these surface interactions without visible damage or alteration.

Features & Benefits

Features

- Five speeds – The standard speed (42 cycles per minute) and four additional speeds (21, 85, 100 and 106 cycles per minute) allow you to decrease the testing time for samples requiring a higher number of rubs

- Additional variable speed ranging from 20-115 cycles per minute

- Infinitely variable cycle count from 1-999

- Continuous cycle mode

- Large character LCD Display

- Displays count up, count down, test status and configurations

- Preset counts remain in memory

- Automatic shut-off

- Selectable “test complete” alarm

- One-year warranty

Technical Specifications

Specifications

- Includes (1) 1.8 kg(4 lb) weight, (1) 0.9 kg(2 lb) weight, spare rubber pads, and scoring fixture

- Heated weights 2 lb and 4 lb available

- Replacement Pads available

Instrument Size

| Depth: | 216 mm (8.5 in.) | ||

| Height: | 229 mm (9 in.) | ||

| Width: | 356 mm (14 in.) | ||

| Weight | 9.5 kg (21 lb) + weights |

Connections

Electrical: Specify voltage requirements when ordering

Applications

Applications

Coating Testing, Ink and Printability Testing, Package Testing, Surface Property Testing

Industries

Adhesives and Labels, Corrugated and Board, Flexible Packaging and Films, Inks and Coatings, Packaging, Paper and Pulp

Properties

Abrasion, Ink Rub