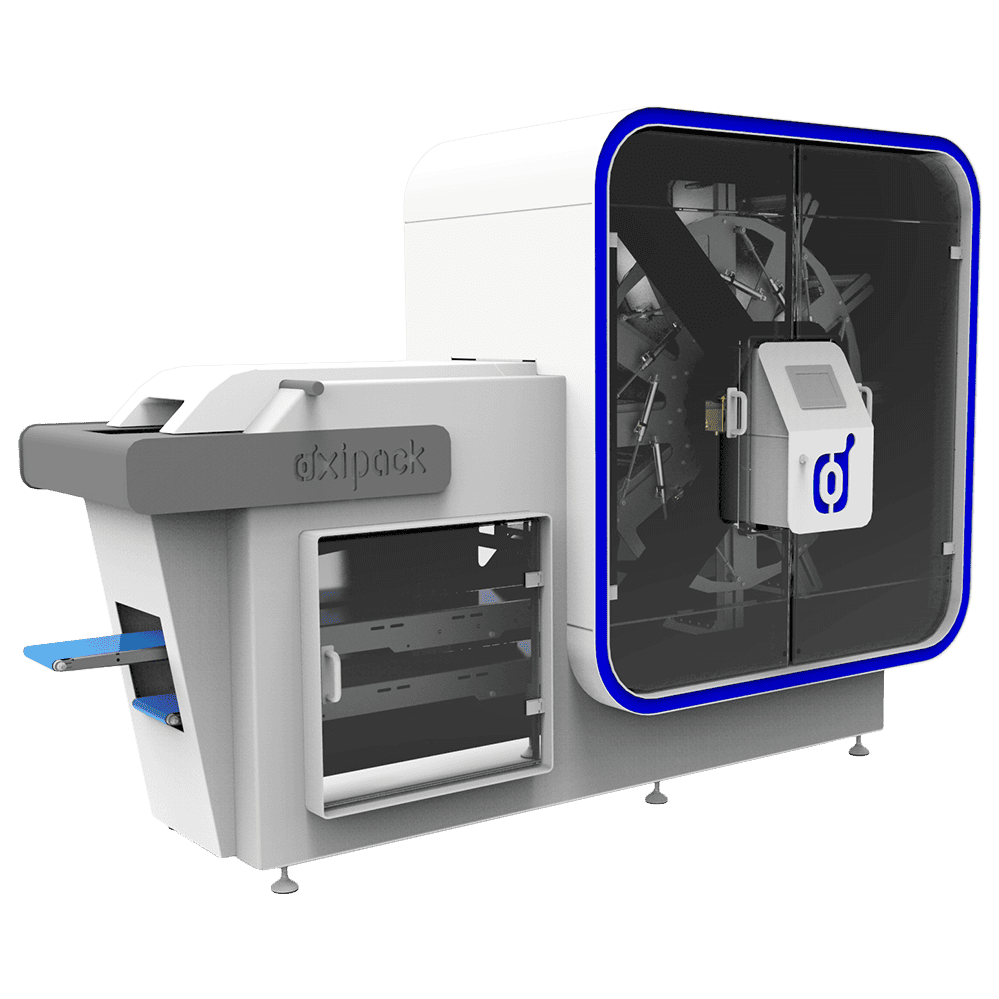

The Rotator R-20-120

These automated inline leak detection solutions integrate seamlessly into production lines, testing flexible MAP packages with precision and efficiency for optimal quality control.

Description

The Rotator R-20 by Oxipack is an automated in-line leak detection system designed for flexible MAP-packages, enabling comprehensive control over both the process and quality of the production line. Capable of testing 20 to 120 packages per minute, it seamlessly integrates into the production line for efficient integrity checks. Its universal chambers allow for the simultaneous testing of various MAP packaging types.

In operation, packages are fed to the Rotator’s conveyor belt, then positioned by a shooting belt into the test chamber. This chamber, comprising a rigid bottom plate and a flexible top membrane, closes to create a vacuum for the leak test. Once tested, packages are sorted onto either reject or OK belts, ensuring only quality packages proceed in the production line. The Rotator R-20 in-line leak detection system stands out for its non-destructive, accurate testing and full integration into production lines, ensuring consistent product quality.

If you are not looking to test in-line, but still want to test multiple packs or sachets simultaneously, take a look at the Stationary Leak Tester XXXL (SLT XXXL) as a possible solution.

Features & Benefits

- Features:

- Automated in-line testing for flexible MAP packaging.

- Integration into production lines.

- Customizable chambers for various packaging types.

- Individual package testing with a robust sorting mechanism.

- Benefits:

- Streamlines production with quality control.

- Flexible testing for different package types.

- High throughput (up to 120 packages per minute).

- Ensures package integrity with direct sorting of defective items.

Technical Specifications

Dimensions and Weight: 3370 x 1100 x 2280 mm (L x W x H) 1825 KG

Power supply: 2P + PE 100 – 230VAC 50/60Hz

Materials: Stainless steel, Anodised aluminium, POM, Polycarbonate

Air supply: 6-8 bar

Compliance and IP rating: CE and IP40

Ambient temperature: 0 – 30 ˚C

Ambient relative humidity: Max 80% (non-condensing)

Size measuring chamber: 350 x 118 x 80 mm (L x W x H)

Maximum testing capacity: 20 PPM

Number of lanes: 1

Number measuring unit: 12

Leak detection method: ASTM F2338

Connections: USB/Ethernet export, 24VDC logic (free programmable)

Packaging type: MAP

Options: Line communication, Automated in and outfeed, Oxipack LED ++ package