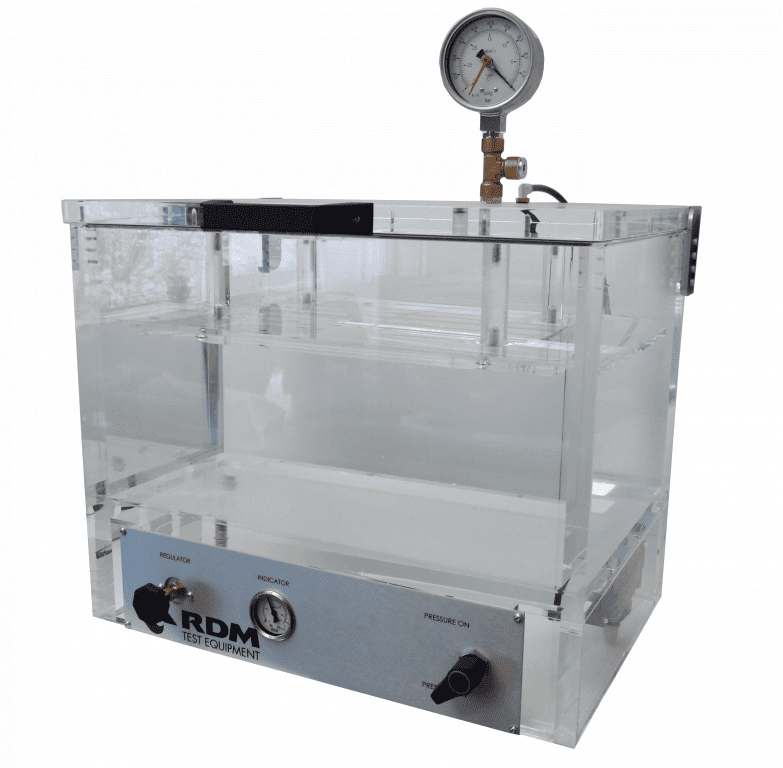

TS-1 Tray Sealer

Production of high quality heat seals, for lidding films on trays, containers, pods, and blister packs.

Description

The TS-1 Tray Sealer is a customisable technology to deliver high quality heat seals for tray / lidding film packaging.

A custom made tray holder and sealing platen are specified for individual sealed packs, or multiple heat seals across a pack.

Tray loading is manual, and the lidding film is either drawn off a small roll or placed manually.

Panel controls give flexible setting of seal parameters, and alerts users to out of tolerance settings, or errors in the sealing sequence.

The robust frame with linear bearing guided operation, optical ‘pack-in-place’ sensors, and interlocked guards, ensure safe and repeatable operation, time after time.

Features & Benefits

Features:

- Precise control of temperature, pressure and dwell time

- Optional storage of recipes for fast and repeatable recall of machine settings

- Precise pressure calibration of standard surface area jaw face

- Jaws constructed in aluminium and silicon rubber with precision ground faces

- Range of jaw face surfaces including Flat Metal, Crimp and Teflon Coating

- Auto start feature and cycle counter with reset, for greater user convenience with multiple samples

Benefits:

- Highly customisable technology to suit the application with heat sealing bar configuration, either single heated or dual heated

- ISO11607, or internal standards

- High quality repeatable seals, not influenced by operator

- Versatile applications for trays, containers, blister packs and pots, custom designs as required

- Low Maintenance – 12 months between calibrations

TS-1 Tray Heat Sealer meets the following standard: ISO11607-2