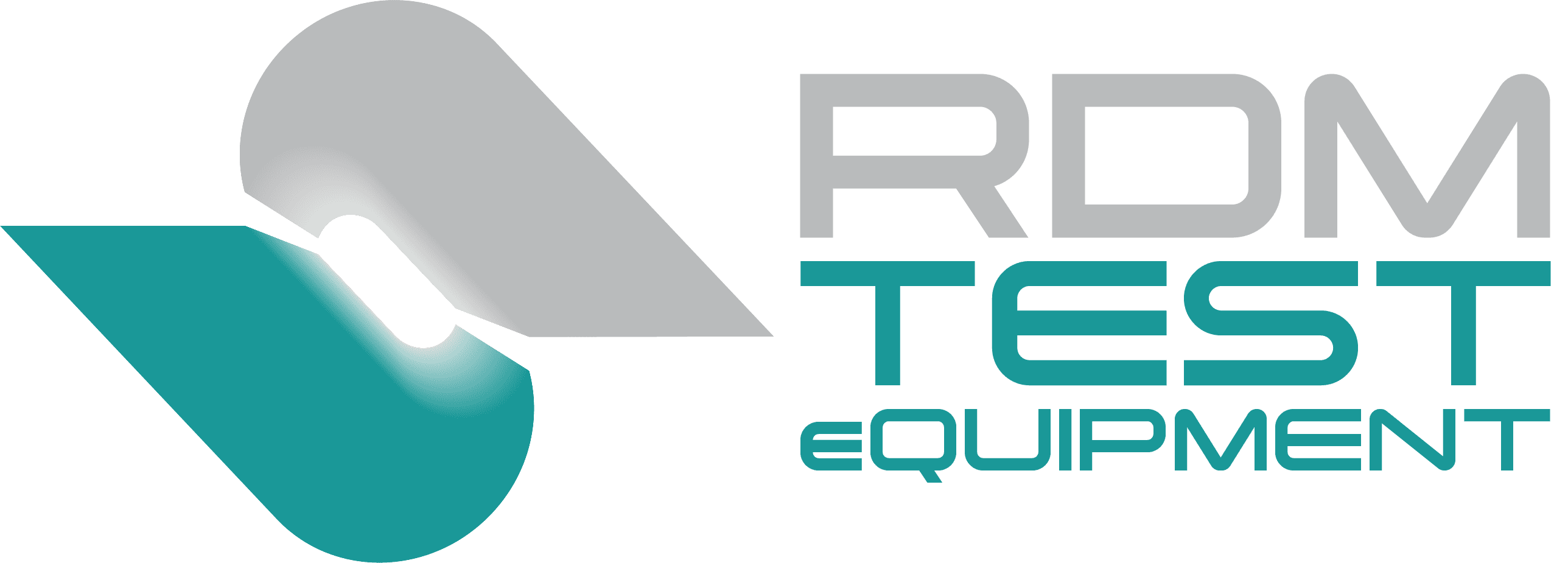

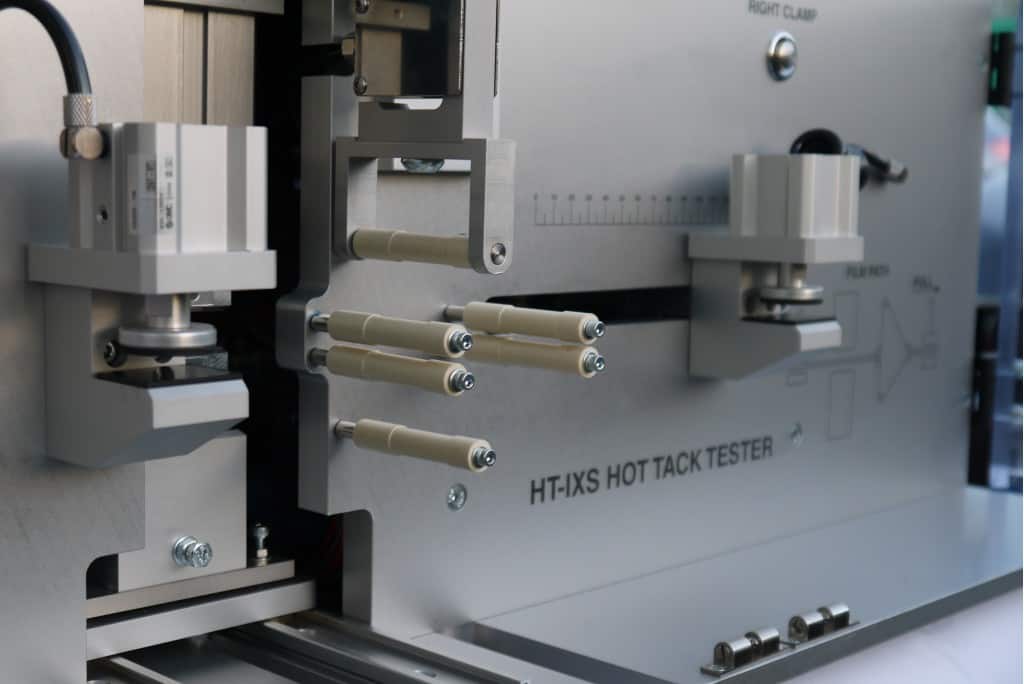

HT-1XS Hot Tack Tester

Touch Screen Precision Hot Tack Tester for determination of the hot tack seal strength of flexible packaging materials, to ASTM F1921.

In vertical (VFFS) and horizontal (HFFS) form-fill operations, heat seals are often subjected to forces whilst still hot. If the hot seals are unable to resist these forces then unsealed areas or holes into the package can occur during the process. The RDM HT-1XS Hot Tack Tester measures the strength of hot seals enabling selection and compliance testing of suitable flexible materials for packaging applications. Precise control of sealing process variables (temperature, pressure, and time) in production then enables an optimal balance between material specification, packaging machine speed and seal integrity.

Description

Accuracy and repeatability in laboratory heat seal testing is vital, and the HT-1XS Hot tack tester provides the technology and reliability to deliver time after time. The HT-1XS seals and then immediately measures the peel strength of the hot seal. An intelligent controller and touch screen user interface provide test setting options, and allows multiple settings to be stored for later recall. Resulting graphs and data of load v time and load v temperature can be viewed, printed and exported to spreadsheets / SPC systems.

Testing is performed in accordance with ASTM F1921. The RDM HT-1XS Hot Tack Tester is used by leading film producers and converters across the world, and is backed by our direct support offices and by our trained service partners worldwide.

HT-1XS Hot Tack Tester meets the following standard: ASTM F1921.

For industrial PC model see the HT-1PC.

Video

Features & Benefits

Features

ASTM F2029-compliant testing of hot tack and cold peel performance with precise control over temperature, pressure and dwell time.

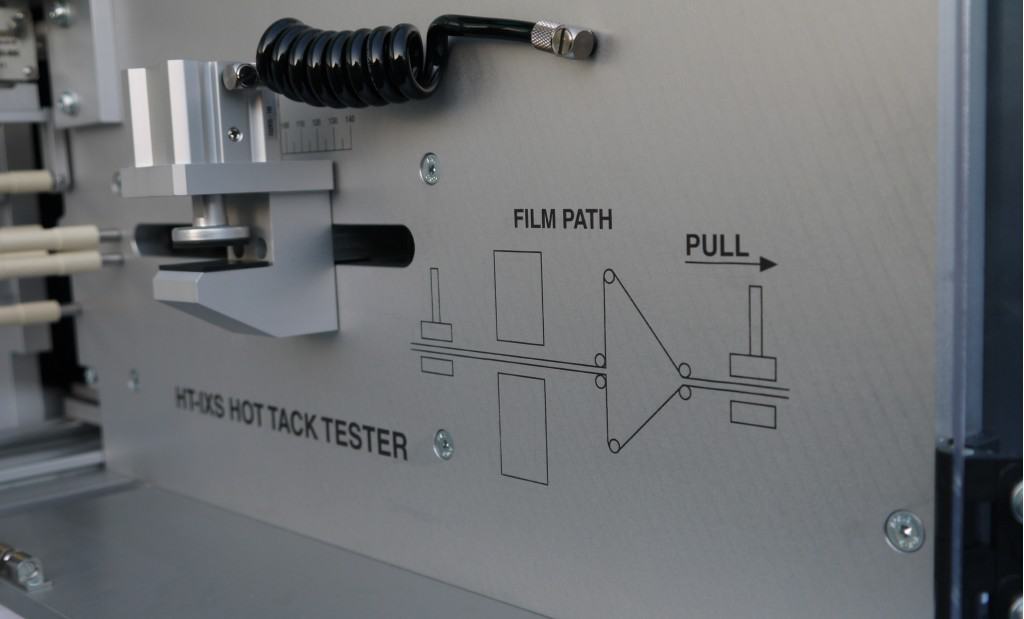

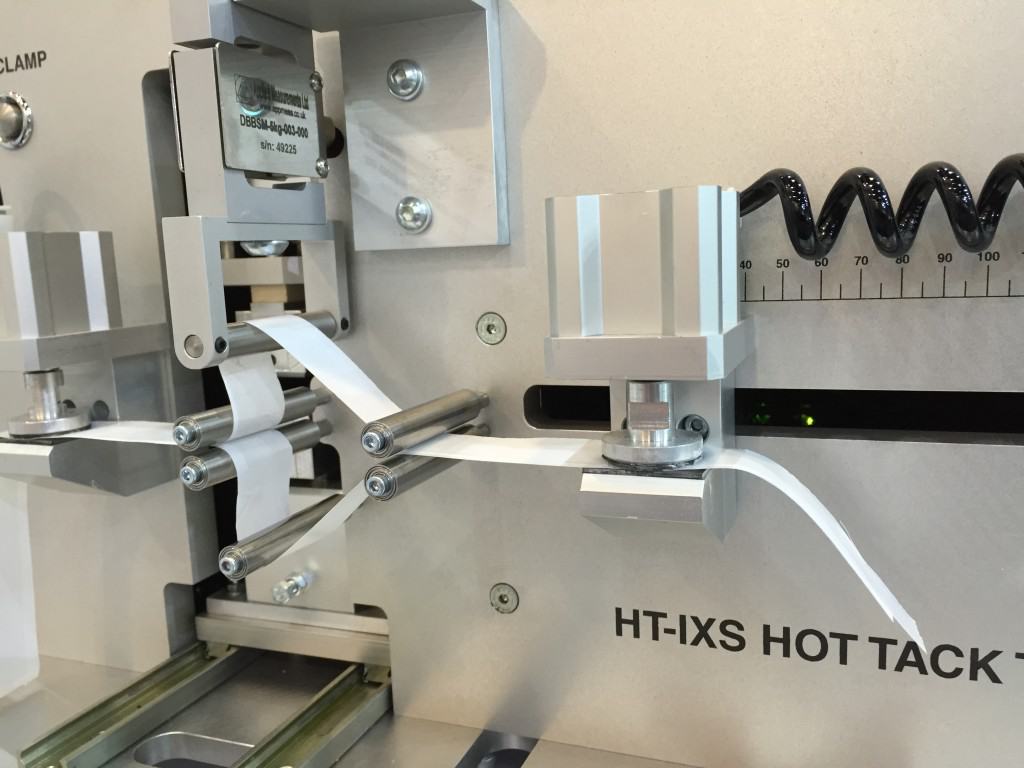

Integrated peel test mechanism automatically measures seal strength at the exact moment the jaws open using a sensitive load cell.

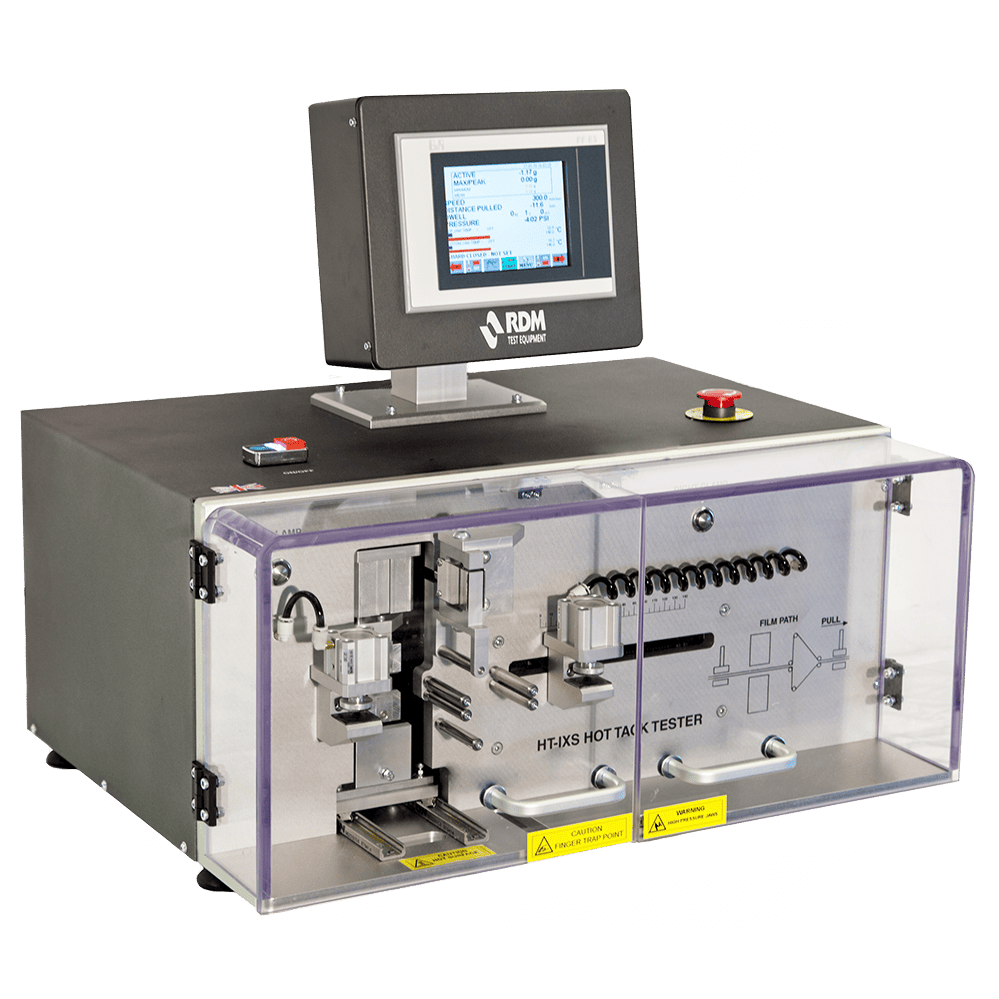

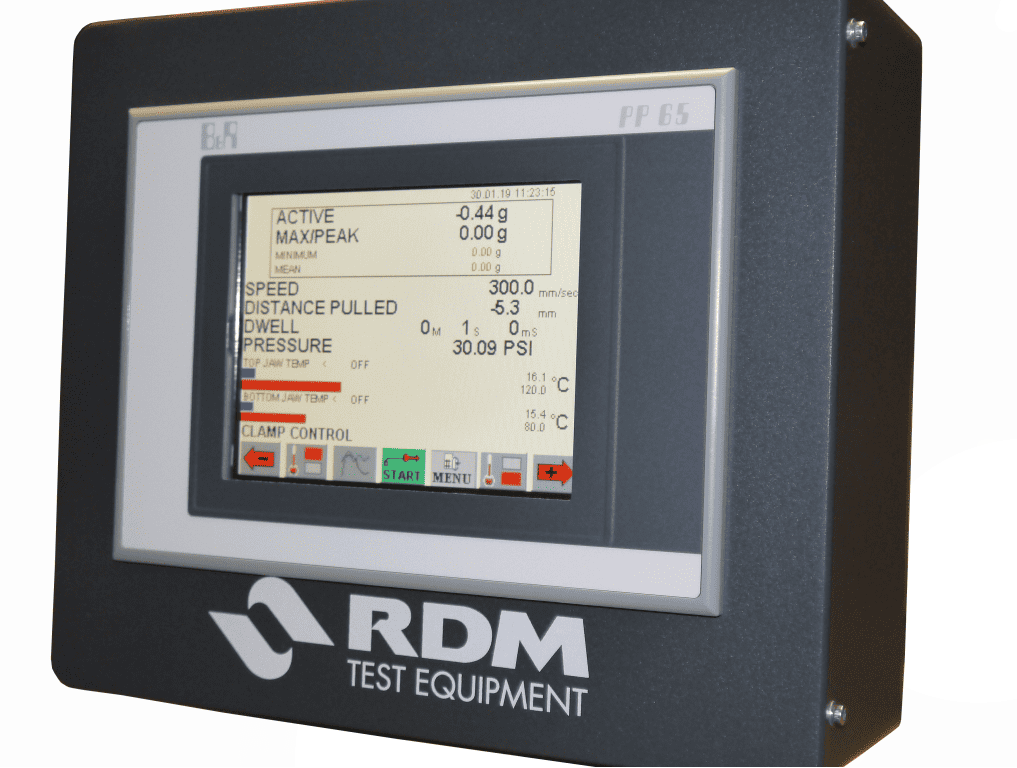

Touchscreen interface with colour LCD, presets and data storage for easy setup, traceability and reporting.

Interchangeable sealing jaws (standard flat, optional crimp or customised) plus adjustable pull speeds from 1 mm/s to 1000 mm/s.

Cold peel capability allows seals to fully cool before testing for ultimate seal strength evaluation.

Benefits

Reliable, repeatable results that meet international standards — ideal for R&D, QA and production environments.

Saves time and reduces operator error by combining sealing and peel testing in one automated cycle.

User-friendly operation with fast setup, minimal training and built-in data capture for audits or SPC.

Flexible testing options let you replicate real-world sealing conditions and optimise packaging materials.

Comprehensive performance insight by comparing hot tack vs cold peel strength for improved package reliability.

Technical Specifications

Touch Screen Panel

LCD, 256 colour QVGA, 320 x 240 pixels, 14.48 cm diagonal viewing.

Touch screen, analogue resistive (gonze) with serial controller.

Processor geode SC2200.

266 MHz MMX compatible. 64 Mb Dram main memory.

Heat Sealing Process

Temperature range – ambient to 250 deg. C +/- 1 deg C reading to 1 deg C, RTD input (deg F can be selected via the screen).

Pressure range – 0 to 100 psi +/- 5 psi (other units can be selected via screen).

Dwell Time range – 0 to 99.999 sec +/- 0.1 sec. Meeting ASTM 2029.

Heat sealing head pneumatically operated to extend for heat sealing cycle and then return to rest position.

Ensures heat is not influencing seal whilst waiting for pull cycle or when cold peel test option selected.

Sealing Jaws

Heated upper and lower ground flat aluminium jaws 25 x 50mm, supplied as standard.

Jaws have an interchangeable feature which enables crimp jaws or customised jaws to be fitted.

Alignment of jaws made through spring mounted lower bolster.

Teflon coating of jaws is an option.

Hot Tack Measuring

Load cell ‘Z’ bend strain gauge range – 2000g or 5000g (20N or 50N) +/- 0.25%.

Pull speed range – 1mm/sec to 1000mm/sec. Manual or automatic return of cross arm to start position. Maximum cross arm.

travel – 100mm.

Travel indication shown on main display panel in mm.

Delay on pull range – 0 to 99min 99sec.

Film clamps

Left and right pneumatic clamps synchronised with pulling operation.

Cold Peel

Allows seal to completely cool and cure before pulling operation takes place producing cold seal

strength measurement.

Cooling Range – 0 to 99hrs 99mins 99sec.

Safety Guard

Micro-switch controlled guard in position feature.

Environment

5-50C ambient operating temperature, RH 75% max (non- condensing)

Power

110V AC or 230V AC 50/60 Hz 1000W

Accessories supplied

1000g calibration weight.

25mm x 350mm sample seal template

Accessories

Options available

Crimp jaws 25 x 50mm, 120 deg x 1.8mm pitch.

Teflon coating to sealing jaws.

Silicone rubber covered lower jaw