Expert Testing For Your Films and Packaging

Our expert team provide thorough permeation and physical testing services to help you identify potential issues before they affect your products. Whether you’re testing for barrier performance or package integrity, we offer timely results and expert advice to give you confidence in the materials you use and meet your regulatory requirements

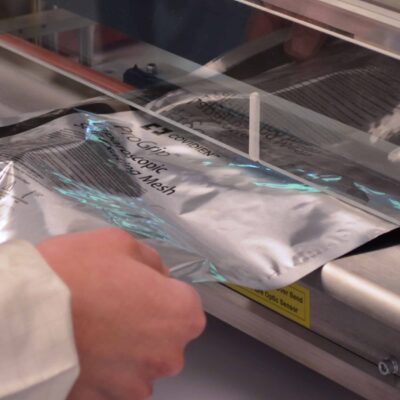

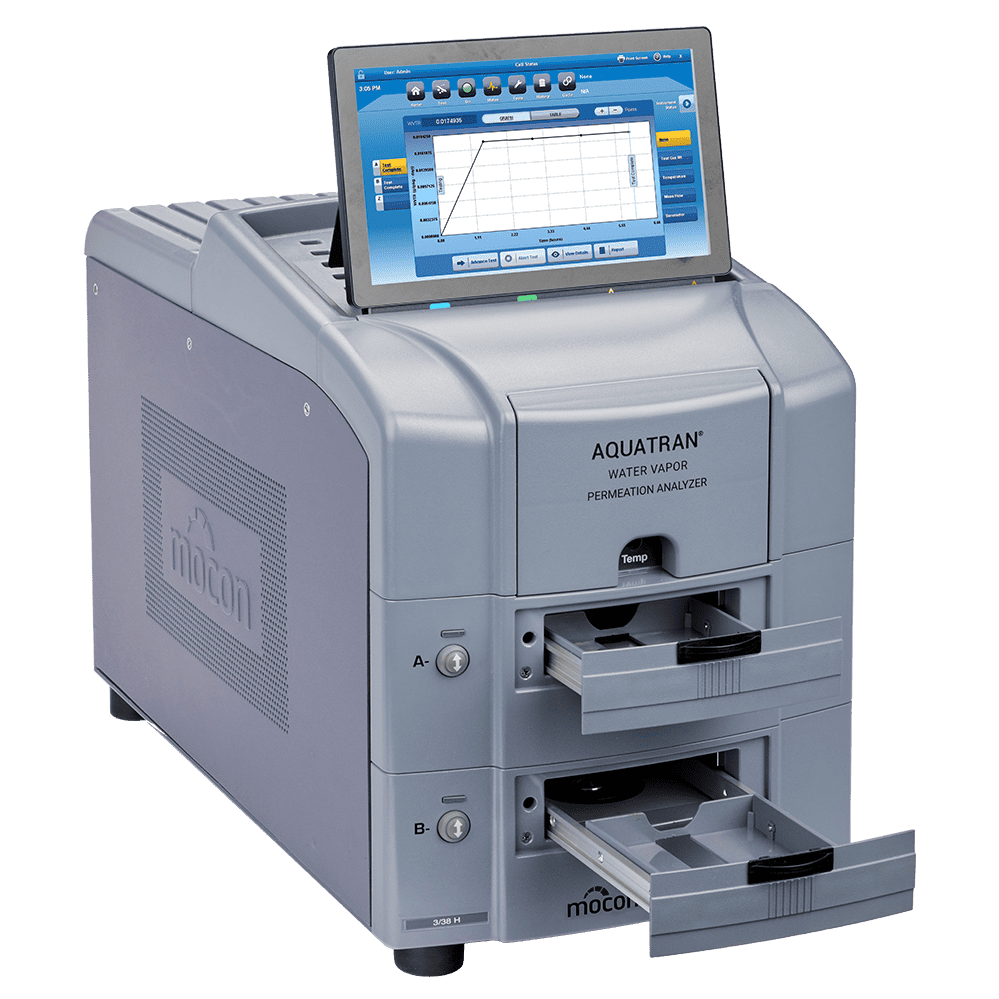

We offer a range of testing services in the material testing lab, including Mocon permeation, heat seal, friction, package integrity, physical strength, and surface and optical testing, to ensure the quality and performance of your materials and packaging

The time frame varies based on the type of service. For most projects, initial results may be visible within a week of receiving the samples. Permeation testing can take a little longer, as some samples need to test for a full 120 hrs to provide sufficient information for our experts to gauge material barrier performance. while full outcomes take longer.

Tackling materials-related issues can be complex and time-sensitive. That’s why we offer a free consultation to discuss your specific needs and identify how we can support you. In addition to expert guidance, we ensure your materials barrier challenges and physical testing requirements are addressed promptly and effectively.

Getting started is simple! Click to contact us or use the “Easy Step” section a little further down this page to request your test.

Frequently Ask Questions for Premeation

Easy Step Process

Getting the results you need for your material and package testing is quick and hassle-free. Just follow the steps below, and we’ll take care of the rest—so you can stay focused on your projects while we handle the testing and deliver the insights you need

If you’re not sure what testing you need or have any question, contact us and the team will be happy to help.

RDM Test Equipment

Unit 39 Golds Nurseries Business Park

Jenkins Drive

Elsenham

Hertfordshire

CM22 6JX

© RDM Test Equipment Ltd. 2025 ~ All rights reserved.